A brand-new treatment that was tested on a high-quality steel alloy results in exceptional plasticity and strength—two characteristics that typically need to be balanced rather than combined. The treatment’s ultra-fine metal grains appear to stretch, rotate, and then elongate under strain in the steel’s outermost layer, conferring super-plasticity in a way that Purdue University researchers are unable to fully explain.

The researchers treated T-91, a modified steel alloy that is used in nuclear and petrochemical applications. However, the researchers said that the treatment could be used in other places where strong, ductile steel would be useful, like car axles, suspension cables, and other structural parts. The research, which has been patented and was carried out in conjunction with Sandia National Laboratories, was published in Science Advances.

More charming even than the quick consequence of a more grounded, more plastic variation of T-91 are perceptions made at Sandia showing qualities of what the group is calling a “nanolaminate” of superfine metal grains. The treatment was made in a locale stretching out from the surface to a profundity of around 200 microns.

“This is a complex process, and the research community has never seen anything like it before. The G-T91 exhibits super-plasticity by definition, but the actual mechanism that enables this is unknown.”

Xinghang Zhang, lead author and a professor in the School of Materials Engineering at Purdue.

According to Xinghang Zhang, lead author and Purdue professor in the School of Materials Engineering, images from microscopy demonstrate an unexpected deformation of the treated steel, which is referred to as G-T91 (or gradient T91).

Zhang stated, “The research community has not previously seen this phenomenon, and this is a complex process.” The G-T91 exhibits super-plasticity by definition, but the precise mechanism that makes this possible is unknown.”

Steel and other metals may appear solid to the naked eye, but when magnified, a metal bar appears to be a collection of individual crystals known as grains. The grains of a metal can deform under strain in such a way that the metallic structure remains intact without breaking, allowing the metal to stretch and bend. Bigger grains can oblige a more prominent strain than more modest grains, leading to a decent compromise between enormous grain deformable metals and little grain solid metals.

Lead author Zhongxia Shang, a former graduate student in Zhang’s lab, broke up large grains on the surface of a T-91 sample into smaller ones using compressive and shear stresses in the Science Advances paper. From the surface, where the smallest ultra-fine grains are less than 100 nanometers in size, to the center of the material, where the grains are 10 to 100 times larger, a cross-section of the sample demonstrates that grain sizes increase.

The modified G-T91 sample outperformed the combined strength and plasticity of standard T-91 by having a yield strength of approximately 700 megapascals, or a unit of tension stress, and by withstanding a uniform strain of approximately 10%.

“This is the magnificence of the construction; the middle is delicate so it can support versatility at the same time; by presenting the nanolaminate, the surface has become a lot harder,” said Shang, presently an exploration staff researcher at Purdue’s Birck Nanotechnology Center. “The large grains in the middle and the nanograins on the surface deform together if this gradient is made. The stretching is handled by the large grains, and the stress is accommodated by the small grains. What’s more, presently, you can make a material that has a blend of solidarity and flexibility.”

While the exploration group had conjectured that the inclination nanostructured G-T91 would perform better compared to standard T-91, examining electron microscopy pictures taken at spans during the pressure testing revealed a secret.

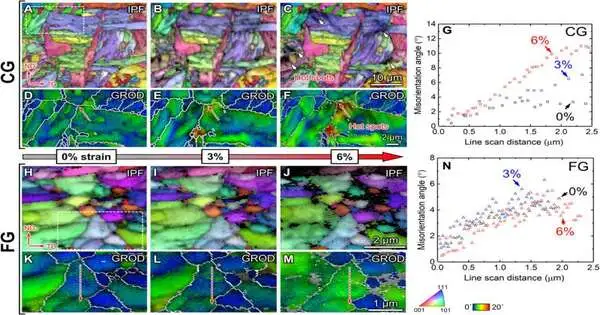

Using a scanning electron microscope at Sandia, electron backscattered diffraction images show how grains in the G-T91 nanolaminate change at increasing intervals of true strain, a measure of plasticity, from 0% to 12%. The team describes the shape of the grains as lenticular at the beginning of the process, when they are vertical. However, they appear to stretch into a more globular shape under increased strain, rotate, and then elongate horizontally.

According to Zhang, the images show the grain boundary, or the interface between the grains, moving, allowing the grains to stretch and rotate and the steel itself to deform plastically. The team now intends to investigate the rules governing this movement in the grain boundaries, which may make it possible to comprehend gradient materials’ fascinating deformation behavior.

“Maybe we can find a better way to arrange the grains if we know how and why they move.” It’s opened up a very interesting potential, but we don’t know how to do it yet,” Zhang stated.

More information: Zhongxia Shang et al, Gradient nanostructured steel with superior tensile plasticity, Science Advances (2023). DOI: 10.1126/sciadv.add9780