The stringent requirements for sustainability and applicability that advanced materials must meet cause them to become more complex over time. By combining physics-based simulations with artificial intelligence, Dierk Raabe and colleagues examined the use of AI in materials science and the unexplored areas it opens. AI has several benefits over conventional simulation techniques, and it will be crucial for the future of material sciences.

In high technology, mobility, infrastructure, green energy, or medicine, advanced materials are urgently needed for daily life. The complexity of chemical compositions, structures, and desired properties, however, places restrictions on traditional methods of finding and investigating new materials. In addition, new materials should include environmentally friendly methods of creation, consumption, and recycling in addition to enabling novel applications.

Researchers from the Max-Planck-Institut für Eisenforschung (MPIE) have reviewed the state of physics-based modeling and talked about how combining these methods with artificial intelligence can open up previously unexplored areas for the design of complex materials. Their viewpoint was published in the journal Nature Computational Science.

“AI is capable of automatically extracting thermodynamic and microstructural features from large data sets obtained from electronic, atomistic and continuum simulations with high predictive power,”

Professor Jörg Neugebauer, director at MPIE and co-author of the publication.

Combining artificial intelligence and physics-based strategies.

Due to the increasingly complex and demanding material properties that must be taken into account in order to meet technological and environmental challenges, alloys are becoming more complex in terms of composition, synthesis, processing, and recycling. Changes in these variables result in modifications to their microstructure, which have an immediate effect on the material’s characteristics. Here, computational materials design methods are of utmost importance.

Today, all of our methods for creating new materials rely on physics-based simulations and experiments. This method has some limitations when it comes to the quantitative prediction of high-dimensional phase equilibria and, in particular, to the resulting non-equilibrium microstructures and properties. In addition, a lot of models relating to microstructure and properties rely on a lot of variables and use simplified approximations. The question of whether and how these degrees of freedom can still account for the complexity of the material remains, says Professor Dierk Raabe, director of MPIE and first author of the study.

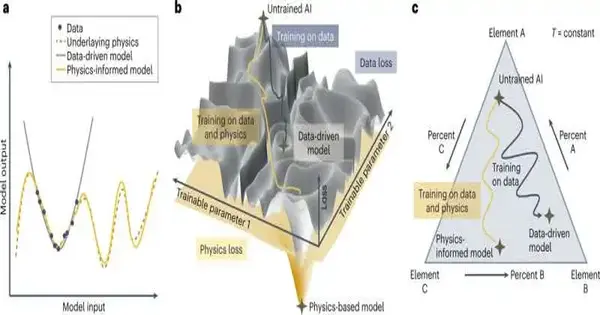

The paper contrasts descriptor-based modeling with advanced artificial intelligence techniques and physics-based simulations, such as molecular dynamics and ab initio simulations. The use of artificial intelligence (AI) has several benefits, whereas physics-based simulations are frequently too expensive to predict materials with complex compositions.

“AI is capable of automatically extracting thermodynamic and microstructural features from large data sets obtained from electronic, atomistic, and continuum simulations with high predictive power,” says Professor Jörg Neugebauer, director at MPIE and co-author of the study.

Utilizing large data sets to improve machine learning.

The availability of large data sets is a barrier that must be overcome because artificial intelligence’s predictive power depends on them. Utilizing active learning cycles, which train machine learning models using initially small subsets of labeled data, is one option. The machine learning model is then run once more after the labeling unit, which feeds high-quality data back into the pool of labeled records, has screened the predictions made by the model. A final high-quality data set that can be used to make precise predictions is produced using this methodical approach.

How to handle sparse and noisy data is just one of many unanswered questions regarding the use of artificial intelligence in materials science. How to approach intriguing anomalies or “misfits.”. How to implement unwanted elemental intrusion from synthesis or recycling But as algorithms are developed, high-quality material datasets become available, and high-performance computing resources become more readily available, artificial intelligence will become more significant in the near future when it comes to designing compositionally complex alloys.

More information: Dierk Raabe et al, Accelerating the design of compositionally complex materials via physics-informed artificial intelligence, Nature Computational Science (2023). DOI: 10.1038/s43588-023-00412-7