Espresso can do a ton of things: wake you up, warm you up, and reduce that existential fear. As indicated by another review, it could likewise assist with diminishing the losses from 3D printing.

That is the vision behind another task driven by Michael Rivera, an associate teacher in the Map Book Organization and Branch of Software Engineering at CU Rock. He and his partners have fostered a strategy for 3D printing a great many items utilizing a glue made completely out of old espresso beans, water, and a couple of other supportable fixings.

The group has previously explored different avenues regarding utilizing coffee beans to create gems, pots for plants, and even, fittingly, coffee cups. The procedure is likewise straightforward enough that it will work, for certain changes, on generally minimally expensive customer-grade 3D printers.

“You can make a great deal of things with espresso beans,” Rivera said. “Furthermore, when you don’t need it any longer, you can toss it back into an espresso processor and utilize the grounds to print once more.”

The gathering introduced its discoveries at the Relationship for Registering Apparatus’ Planning Intuitive Frameworks meeting in Pittsburgh.

For Rivera, the task is important for his central goal to make 3D printing more supportable—permitting specialists, planners, architects, and more to rapidly make graspable models and other family objects without adding to landfills.

“Our vision is that you could simply get a couple of things at a general store or on the web and get rolling,” Rivera said.

Credit: College of Colorado at Stone

Smart thoughts come from caffeine.

That vision typically starts in a bistro.

At the point when Rivera was an alumni understudy at Carnegie Mellon College, he frequently worked out of a bistro in Pittsburgh called Arriviste Espresso Roasters. The bistro contracted with a nearby gathering to get its pre-owned espresso beans for treating the soil; however, during the coronavirus pandemic, that was beyond the realm of possibilities. The waste started to stack up.

“The proprietor told me, ‘I don’t have the foggiest idea how to manage it. So I simply discard it,'” said Rivera, who joined CU Rock as a postdoctoral specialist in 2022. “I took a gander at the grounds and said, ‘Perhaps I can accomplish something with them.'”

Rivera made sense of the fact that most customer 3D printers available today print with thermoplastics or some likeness thereof. The most well-known is polylactic acid, or PLA. This material is, hypothetically, compostable; however, only a small part of fertilizing the soil will acknowledge it.

“In the event that you toss it in a landfill, which is where most of PLA winds up, it will take as long as 1,000 years to decay,” Rivera said.

He understood he could take care of a few issues simultaneously: reduce plastic waste, track down something to do with that multitude of utilized grounds, and partake in a few warm cups of espresso all the while.

Whenever you’re done with 3D-printed espresso objects, you can throw them into a processor and reuse the material to print again. Credit: Michael Rivera

Reasons for festivity

The group’s strategy is basic, Rivera noted. He and his partners blend dried espresso beans with two different powders that they purchase on the web: cellulose gum and thickener. Both are normal added substances in food and corrupt effectively in a manure container. Then, the scientists blended in water.

“You’re essentially going for the consistency of peanut butter,” Rivera said.

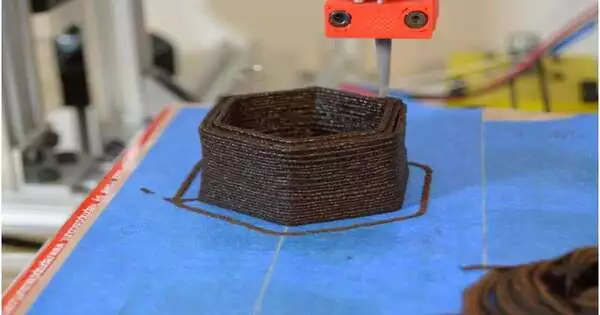

You can’t stack that overflow straightforwardly into a 3D printer. In the first place, Rivera does a little jury-fixing, changing a printer with plastic cylinders and a needle loaded up with espresso glue. In any case, the gathering’s manifestations are shockingly strong. At the point of drying, the coffee bean material is similarly intense as unreinforced concrete.

“We’ve made objects with a lot of utilization,” Rivera said. “We’ve dropped them, and they haven’t broken at this point.”

He sees a great deal of potential for transforming coffee beans into unmistakable items. Rivera, for instance, has made little growers out of coffee beans, which can be utilized to develop seedlings for corrosive ornamental plants like tomatoes. When the plants get sufficiently tall, you can establish them, pot and all, in the dirt. The group can likewise add activated charcoal to its grounds to create parts that can generate power, like buttons for manageable gadgets.

A 3D printer uses espresso beans to make a blossom grower. Credit: Michael Rivera

Rivera noticed that printing with coffee beans might very well never have turned into an inescapable practice. All things being equal, he considers the undertaking to be a stage toward finding different sorts of reasonable 3D printing materials that could, at some point, supplant plastics.

More information: Michael L. Rivera et al, Designing a Sustainable Material for 3D Printing with Spent Coffee Grounds, Proceedings of the 2023 ACM Designing Interactive Systems Conference (2023). DOI: 10.1145/3563657.3595983