Organic solar cells (OSCs) are attractive owing to their lightweight, flexibility, and high power conversion efficiency. However, a lack of morphology control of the active layer makes it challenging to develop OSCs with large active areas. Now, researchers from Gwangju Institute of Science and Technology, Korea take things to the next level by using water treatment for morphology control in the fabrication of active layer thin films, improving the performance and stability of large-area OSCs.

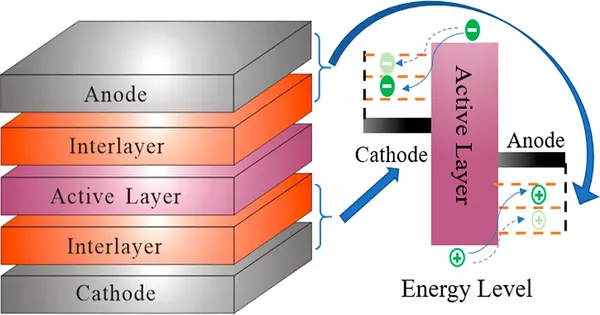

Organic solar cells (OSCs), which use organic polymers to convert sunlight into electricity, have received considerable attention in recent times for their desirable properties as next-generation energy sources. These include lightweight, flexibility, scalability, and high power conversion efficiency (>19%). Currently, several strategies exist for enhancing the performance and stability of OSCs. However, a problem that lingers on is the difficulty of controlling the morphology of the active layer in OSCs when scaling up to large areas. This makes it challenging to obtain high-quality active layer thin films and, in turn, fine-tune the device’s efficiency.

In a recent study, a team of researchers from the Gwangju Institute of Science and Technology, Korea set out to address this issue. In their work, published in Advanced Functional Materials, they suggested a solution that appears rather counterintuitive at first glance: using water treatment to control the active layer morphology.

We observed that the water-treated active solution led to a more uniform active layer thin films, which showed higher power conversion efficiencies compared to those not treated with water. Moreover, we fabricated large-area OSC modules with an active area of 10 cm2, which showed a conversion efficiency as high as 11.92% for water-treated H-NF films.

Prof Kim

“Water is known to hinder the performance of organic electronic devices, since it remains in the ‘trap states’ of the organic material, blocking the charge flow and degrading the device performance. However, we figured that using water rather than an organic solvent-based active solution as a medium of treatment method would enable necessary physical changes without causing chemical reactions,” explains Professor Dong-Yu Kim, who headed the study.

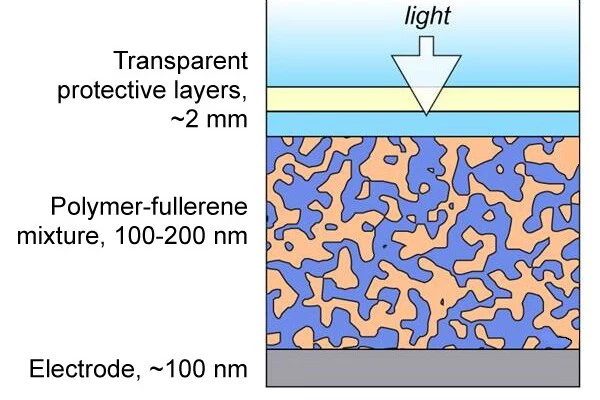

The researchers chose the polymers PTB7-Th and PM6 as donor materials and PC61BM, EH-IDTBR, and Y6 as acceptor materials for the active layer. They noticed that inducing a vortex to mix the donor and acceptor materials in the active solution could lead to a well-mixed active solution, yet it was not enough on its own. The active solution was hydrophobic and, accordingly, the researchers decided to use deionized (DI) water and vortices to stir the solution. They let the donor and acceptor materials sit in chlorobenzene (host active solution) overnight, and then added DI water in the solution and stirred it, creating tiny vortices.

Due to the hydrophobic nature of the solution, the water pushed on the donor and acceptor molecules, causing them to dissolve more finely into the solution. They then let the solution rest, which caused the water to separate from the solution. This water was then removed and the water-treated active solution was used to prepare thin films of PTB7-Th: PC61BM (F, fullerene), PTB7-Th: EH-IDTBR (NF, fullerene), and PM6: Y6 (H-NF, high-efficiency non-fullerene).

The researchers then examined the photovoltaic performance of these thin films in a slot-die-coated inverted OSC configuration and compared them with those for OSCs without water treatment.

“We observed that the water-treated active solution led to a more uniform active layer thin films, which showed higher power conversion efficiencies compared to those not treated with water. Moreover, we fabricated large-area OSC modules with an active area of 10 cm2, which showed a conversion efficiency as high as 11.92% for water-treated H-NF films,” highlights Prof Kim.

Overall, this study provides a guideline for developing large-scale, efficient OSCs using a remarkably easy, economical, and eco-friendly method, which can open doors to their realization and commercialization.