Natural scientists at Flinders University are investigating additional viable options, with a focus on building materials made from byproducts.

In yet another step into the circular economy, scientists from the Flinders Chalker Lab used low-cost feedstocks to create lightweight yet solid polymer building blocks that can be fortified with a glue-free compound response.

Their most recent review tested the strength of these materials and investigated ways they can be built up in development.

Justin Chalker, Matthew Flinders Professor of Chemistry, says the need to foster feasible structural materials is progressively significant, with concrete, iron, and steel production representing over 15% of worldwide CO2 outflows every year.

“This novel catalytic process produces a sustainable construction material with its own mortar and exhibits very strong bonding, potentially streamlining construction,”

Dr. Maximilian Mann

“In this review, we tried another kind of block we can make from squander cooking oil, blended in with sulfur and dicyclopentadiene (DCPD). Both sulfur and DCPD are products of oil refining.

“The blocks bond together without an endless supply of a following measure of amine impetus.”

“Every one of the starting materials is ample and can be called modern waste.

“This examination is essential for the bigger work to move towards a feasible fabricated climate,” says project pioneer Professor Chalker.

The Chalker Lab’s new polymer research group at Flinders University’s College of Science and Engineering is teaming up with Clean Earth Technologies for an additional turn of events. increase and conceivable commercialization.

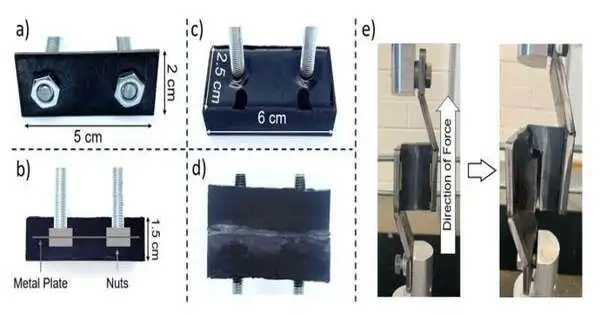

The most recent review, published as a cover highlight in a unique issue on sustainability in the journal Macromolecular Chemistry and Physics, extended the examination to test the new blocks’ mechanical properties and take a gander at ways of supporting them in development, incorporating carbon fiber fillers.

Chalker Lab research partner Dr. Maximilian Mann says as well as reusing waste materials into esteem-added development materials, the polymer blocks’ sulfur bond implies they can be bound together without mortar like customary structure strategy.

“The holding in this clever reactant process areas of strength is a feasible development material with its own mortar which will possibly smooth out development,” Dr. Mann says.

More information: Maximilian Mann et al, Chemically Activated SS Metathesis for Adhesive‐Free Bonding of Polysulfide Surfaces, Macromolecular Chemistry and Physics (2021). DOI: 10.1002/macp.202100333