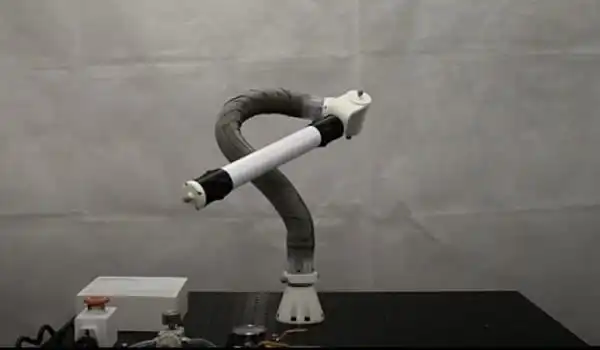

A bendable robotic arm that can be directed into shape by a person wearing augmented reality (AR) goggles has been developed by researchers. Many robotic arms are built with rigid joints and limbs to ensure strength, but the researchers sought to design a flexible arm that could be utilized in a variety of applications.

Malleable robots are a type of reconfigurable robot that can help with a range of applications, including spacecraft repair, manufacturing, and even injury rehabilitation.

The flexible arm, which was designed and created at Imperial College London, can twist and bend in all directions, making it easily adaptable for future applications in manufacturing, spaceship repair, and even injury rehabilitation. To ensure perfect alignment, the arm can be manually guided into shape utilizing mixed reality smart glasses and motion tracking cameras.

Instead than being confined by inflexible limbs and solid joints, the adaptable arm is easily bendable into a broad variety of configurations. In fact, people working alongside the robot would manually bend the arm into the precise shape required for each operation, a level of flexibility made possible by the slippery layers of mylar sheets inside, which slide over one another and may lock into position. However, configuring the robot into specific shapes without guidance has proven to be difficult for users.

We’ve demonstrated how augmented reality can make it easier to collaborate with our bendable robot. The method provides customers with a variety of simple-to-create robot positions for a variety of applications, without requiring a high level of technical skill.

Dr. Nicolas Rojas

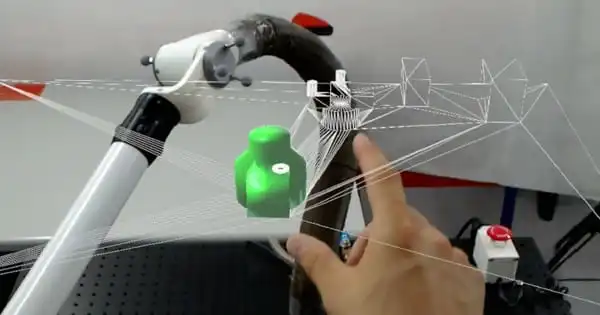

Layers of slippery mylar sheets slide over one other and may be locked into place when the arm is in the proper position, making the arm bendable. The user can see templates by wearing augmented reality (AR) goggles, which superimpose the correct location onto the user’s environment. When the arm is in the proper position, the template becomes green.

To improve the robot’s usability, researchers at Imperial’s REDS (Robotic manipulation: Engineering, Design, and Science) Lab created a system that allows users to view in AR how to customize their robot. Users see templates and designs superimposed on their real-world environment while wearing mixed reality smart glasses and motion tracking cameras. They next adjust the robotic arm until it fits the template, which lights green upon successful setup and allows the robot to be secured into place.

“One of the fundamental problems in adjusting these robots is accuracy in their new position,” stated Dr. Nicolas Rojas of Imperial’s Dyson School of Design Engineering. We humans aren’t excellent at ensuring that the new position matches the template, which is why we turned to artificial intelligence for assistance. We’ve demonstrated how augmented reality can make it easier to collaborate with our bendable robot. The method provides customers with a variety of simple-to-create robot positions for a variety of applications, without requiring a high level of technical skill.”

The method was tested on five males aged 20 to 26 who had prior experience with robotics but no prior experience with handling bendable robots. The subjects were able to precisely modify the robot, and the findings were published in Robotics & Automation Magazine.

Despite the small number of participants, the researchers believe their first findings demonstrate that, with additional testing and user training, AR could be a successful technique of adapting flexible robots.

Bent into shape

Manufacturing, construction, and vehicle maintenance are all possible applications. Because the arm is so light, it could be employed on spacecraft where light instruments are preferred. It is also soft enough to be used in injury rehabilitation, assisting a patient in performing one exercise while their physiotherapist performs another.

PhD researchers Alex Ranne and Angus Clark, both from the Dyson School of Design Engineering, stated as co-first authors: “It resembles a detached, bendier third arm in many aspects. It could be useful in a variety of scenarios when an extra limb would be useful in spreading the effort.”

The researchers are still working on perfecting the robot as well as its AR component. They will then look into incorporating touch and audio aspects into the AR to improve its accuracy in configuring the robot.

They are also looking into reinforcing the robots. Although their flexibility and softness make them easier to configure and possibly even safer to operate alongside people, they are less rigid when locked, which may impact precision and accuracy.