3D printing can create exceptionally complex shapes. Yet, printing fired objects with the assistance of a laser is a more troublesome test. Presently, scientists at the Paul Scherrer Establishment (PSI) have taken interesting tomograms, uncovering what occurs at a tiny level during this manufacturing interaction. The discoveries will assist with working on this extremely encouraging innovation.

3D printing is now being utilized to deliver many items. Added substance fabrication is progressively being utilized in the aviation and car industries, for instance, as well as in medication.

The technique generally utilized for metals and plastics is known as laser-based powder bed combination (LPBF). In LPBF, the material is applied as a fine powder layer on a substrate, and afterward, the laser disregards the powder and melts it to frame it into the ideal shape. The following slender layer of powder is saved and, by and by, softened by the laser. The part is developed successively along these lines, layer by layer.

Precisely what occurs during the LPBF interaction has been proactively examined utilizing X-beams at the Swiss Light Source SLS at PSI and individual examination foundations; however, these infinitesimal experiences have only given 2D pictures to date.

“It would be a lot easier if such components could be printed, However, when printing aluminum oxide, it remains difficult to obtain a sufficiently dense material with the desired microstructure.”

says PSI physicist Steven Van Petegem.

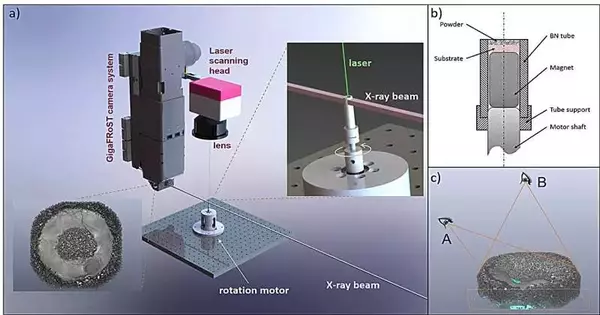

“We needed to go above and beyond and track the assembling system in 3D,” says Malgorzata Makowska, material researcher at PSI. Rather than 2D X-beam pictures, the scientists needed to get 3D tomograms at a speed permitting them to follow the laser spot. To do as such, they needed to follow their example during the assembly system and track this quick, revolving development with the laser—a significant test. Interestingly, the group has now figured out how to do this, as detailed in the diary correspondence materials.

The video shows how the example powder sets were affected by the laser to shape the PSI lettering. Credit: Paul Scherrer Establishment/Malgorzata G. Makowska

A magnet balances out a pivoting forerunner powder.

The researchers used aluminum oxide for their examinations. This fired material is regularly utilized, for instance, in the substance business for parts presented to high temperatures, in electrical design as a protector, or in medication for inserts. Since this material is very hard and weak, creating complex shapes with customary innovation presents colossal difficulties.

“It would be a lot simpler if one would print such parts,” says PSI physicist Steven Van Petegem. “While printing aluminum oxide, nonetheless, it’s as yet challenging to get an adequately thick material and the ideal microstructure.”

The investigations led to the SLS tomography beamline. Tomcat offered new experiences in the inventive assembly process. The test pivoted at a speed of 50 Hz (3000 rpm), while the laser went over the powder. Adjusting the printing system to this incredibly fast turn was one of the principal challenges, which the scientists have now survived.

One more test was to prevent the pivoting material from floating apart because of divergent powers. They accomplished it by putting a tiny amount of attractive iron oxide into the aluminum oxide powder particles and then consolidating a magnet to keep the powder set up. The magnet was mounted underneath the example in a little chamber with a 3 mm measurement.

“Because of the quick GigaFRoST camera, an in-house PSI improvement, and a profoundly productive magnifying lens, it was feasible to procure 100 3D pictures each second during the printing system,” says beamline researcher Federica Marone. These pictures show what has been going on with the powder during the laser treatment.

“Interestingly, we had the option to straightforwardly picture the liquefied volume in 3D,” says Makowska. The state of the supposed ‘dissolve pool’ astonished the analysts. At the point when they expanded the force of the laser, no downturn was framed on a superficial level, true to form. “Rather, the liquefy pool spread out like a flapjack, and the surface was pretty level,” the material researcher remarks.

Printing the ideal microstructure

The analysts could likewise see how pores and hollows formed as the material solidified, which is significant for future applications. “In a perfect world, one might want to have a smooth, appealing material with a distinct microstructure. However, a specific measure of porosity is likewise entirely alluring for explicit applications,” makes sense to Makowska.

Van Petegem adds, “We trust our examinations will uncover more about the printing system and that we can pass on this information, so it tends to be put to commonsense use, regardless of whether there is still far to go.” The redesign of the SLS machine, beginning soon, and the new TOMCAT 2.0 beamlines coming into activity in 2025 will upgrade the ongoing capacities. “It will become conceivable to concentrate on denser material with higher spatial and worldly goals, which are key perspectives for bringing the LPBF innovation further,” says beamline researcher Christian Schlepütz.

The review was made with the coordinated effort of the innovation skill focus of Move AG, ETH Zurich, and Empa. The idea for this examination was a development of the Fuorclam project sent off in 2017 inside the casing of an Essential Center Region (SFA) High Level Assembling program.

“The different activities have offered us the chance to get to know every one of the gatherings in Switzerland that participated in examinations into added substance assembling and 3D printing,” says Van Petegem. “This is a critical point for the future, which Switzerland has recognized.”

More information: Malgorzata G. Makowska et al, Operando tomographic microscopy during laser-based powder bed fusion of alumina, Communications Materials (2023). DOI: 10.1038/s43246-023-00401-3 www.nature.com/articles/s43246-023-00401-3