Capacitors are energy-storing devices made up of two cathodes and an electrolyte that can be charged and discharged quickly due to charge adsorption and desorption properties at the terminal electrolyte interface.Since capacitors’ energy stockpiling doesn’t include compound responses, their capacity limit is lower than that of lithium-particle batteries, yet they are helpful for power even out for sustainable power that requires continued charging at high flows, regenerative slowing down energy for trains and electric or mixture vehicles, as well as quick voltage drop pay gadgets that forestall gear disappointment because of lightning strikes. They are also expected to be utilized to store energy for wearable gadgets soon.

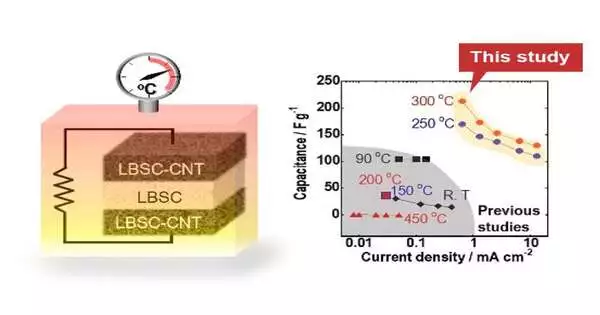

Most capacitors utilize a fluid electrolyte with a low limit, which must be utilized at temperatures below 80 oC. Clay capacitors that utilize strong inorganic materials as a dielectric can be utilized at temperatures above 80 °C, but their capacity limit is a lot lower than fluid electrolyte capacitors, which restricts their utilization to electronic circuits.

To build the energy storage capacity of capacitors, having a huge contact region at the connection point between the cathode and the electrolyte is vital. Making a large contact region with strong electrolytes is difficult; thus, the development of a capacitor with a high capacity limit that can also work at high temperatures has been desired for quite some time.

“The key to creating this capacitor was to use the solid oxide electrolytes that we have been developing for all-solid-state lithium batteries—which combine high deformability with lithium-ion conductivity—to capacitors.”

Professor Akitoshi Hayashi at the Graduate School of Engineering

An examination group led by Professor Akitoshi Hayashi at the Graduate School of Engineering, Osaka Metropolitan University, has fostered a strong electrolyte that is profoundly deformable, permitting it to have a huge contact region with a cathode, which was created to be utilized for an oxide-based all-strong state battery.

In this review, they created a composite utilizing a similar profoundly deformable strong electrolyte and carbon, then utilized it to build the two cathodes for a mass-produced all-strong state capacitor. This capacitor is able to do high current densities and high-limit charging and releasing at temperatures of 200-300 °C, making it the world’s most memorable mass-produced all-strong state capacitor. The analysts expect that their capacitor will be utilized to further develop innovation for high-temperature conditions, which couldn’t be grown already because of these specialized limits.

The way to understand this capacitor was to take the strong oxide electrolytes that we have been creating for all-strong state lithium batteries — which combine great deformability and lithium-particle conductivity — and apply them to capacitors,” made sense to Professor Hayashi.

Later on, scientists desire to build all-strong state mixture capacitors with much higher energy densities by controlling the compound response between a strong electrolyte and carbon, then joining them with positive cathode materials utilized in lithium-particle batteries.

The exploration was published in the Journal of Power Sources.

More information: Takashi Hakari et al, Thermally stable bulk-type all-solid-state capacitor with a highly deformable oxide solid electrolyte, Journal of Power Sources (2022). DOI: 10.1016/j.jpowsour.2022.231821

Journal information: Journal of Power Sources