A new, low-cost material that can be used to make lenses for thermal imaging has been discovered by Flinders University researchers, pointing to new advanced manufacturing applications for this powerful technology.

Many industries, including defense, security, and surveillance, medicine, electrical engineering, space exploration, and autonomous vehicle operation, use thermal and infrared imaging. However, the necessary materials are expensive and becoming more difficult to find.

A chemistry and physics team at Flinders University has come up with a solution in a brand-new polymer material made from sulfur and cyclopentadiene because cheaper alternatives are needed. They say the elite exhibition polymers have the novel capacity to communicate infrared light.

In a new article published in the Advanced Optical Materials journal, Ph.D. candidate Sam Tonkin, the first author, states, “The material combines high performance, low cost, and efficient manufacturing.”

“It has the potential to broaden the application of thermal imaging to new industries that were previously restricted by the high cost of germanium or chalcogenide lenses. This is a quickly evolving sector that will witness interesting advancements in the next years.”

Ph.D. candidate Sam Tonkin, first author in a new article.

“It can possibly expand the utilization of warm imaging to new businesses that were recently restricted by the significant expense of germanium or chalcogenide focal points. This is a rapidly developing field that will see energizing advances in the following couple of years,” he says.

Petroleum refining generates millions of tons of sulfur annually. Billions of tons are accessible in land stores. It’s cheap and plentiful.

Cyclopentadiene is additionally obtained from minimally expensive materials created in gasoline refining.

Glasses made of germanium or chalcogenide are currently used to make the lenses for thermal imaging. Germanium is a hard component to find, and it is pricey. Some germanium focal points can cost a large number of dollars.

Chalcogenide glasses likewise have weaknesses. For example, they are frequently made of harmful components like arsenic or selenium.

Co-creator Dr. Le Nhan Pham, a Flinders College specialist in computational and actual science, says reacting sulfur and cyclopentadiene together gives a dark plastic with high straightforwardness to infrared light.

“The light that is picked up by thermal imaging cameras is this one.

He asserts, “This novel material was designed to have a wide range of potential applications, from space engineering to military operations, as well as the civil and aerospace industries.”

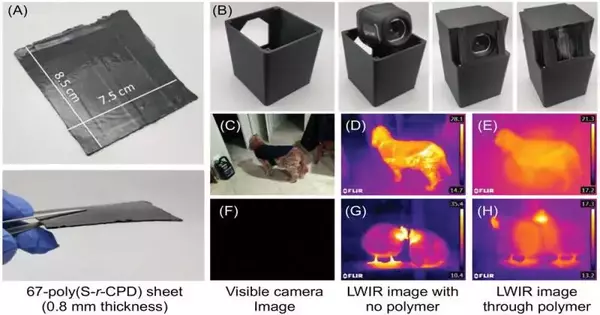

The polymer can be shaped into different focal points, which can be utilized, for instance, to amplify the picture in a warm camera. The black polymer can also be utilized to conceal and safeguard thermal imaging equipment. As a result, the polymer can be used to disguise a surveillance camera.

The infrared light goes through the polymer, so one can see through it using an infrared camera. Wildlife monitoring and defense operations both benefit from this property.

The polymer additionally has numerous different highlights:

- The material has the most elevated long-wave infrared light straightforwardness at any point detailed for a plastic.

- The cost of the raw materials is low: for a 1 g focal point, the structure blocks cost under 1 penny.

- The material permits fast embellishment into different shapes, like focal points. Compared to the slow milling methods used in current lens production, this is a more rapid process.

The concentrate likewise revealed a few critical logical advances, including another reactor that was intended to empower the key response. The ability to utilize the building blocks in a gaseous state was a major obstacle. The utilization of vaporous monomers was previously thought not to be imaginable by different analysts nearby.

Quantum mechanical calculations are also used in the study to figure out how and why the material is transparent to infrared light used in thermal imaging. These insights will also be useful in the design of new lenses with even better properties in the future.

More information: Samuel J. Tonkin et al, Thermal Imaging and Clandestine Surveillance using Low‐Cost Polymers with Long‐Wave Infrared Transparency, Advanced Optical Materials (2023). DOI: 10.1002/adom.202300058