Researchers have found a method for planning materials that further develops energy proficiency in a cutting-edge way that could be useful to the battle against environmental change, make fabricating greener, and really remove the problem of charging your savvy.

The thermoelectric energy gathering development distinguishes a better approach for outfitting beforehand undiscovered wellsprings of waste intensity and changing them into power.

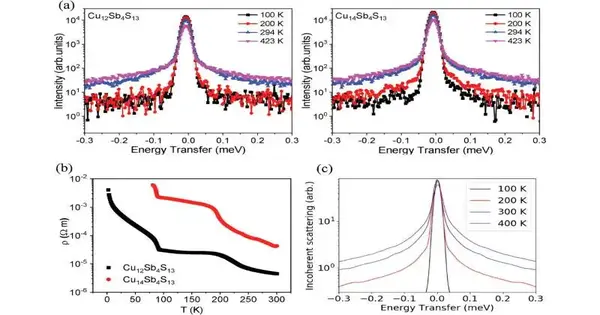

Thermoelectric materials can transform temperature contrasts into power. Specialists at Perusing have found that assuming a thermoelectric material has moving particles inside confines, the intensity stream will be decreased. This keeps the hot and cold sides at various temperatures, while electrons can move from the hot side to the virus side, so power can be made.

As a rule, materials with dropping particles separate while making power like this. In any case, the material portrayed in the new review distributed in Cutting Edge Materials doesn’t separate effectively and could permit gadgets and generators to transform squandered heat into helpful power more proficiently than in current plans.

“This discovery has the potential to contribute to addressing the global energy crisis and combating climate change. Approximately two-thirds of all energy produced in the world is squandered as heat. Even converting a small portion of this waste heat into useable power would contribute to a more sustainable energy supply and lower carbon emissions.”

Dr. Paz Vaqueiro, of the University of Reading’s Department of Chemistry, led the study.

Dr. Paz Vaqueiro, of the College of Perusing’s Branch of Science, drove the review. She said, “This disclosure can possibly assist with addressing the worldwide energy emergency and add to fighting environmental change. Around 66% of the energy produced overall is squandered as intensity. Changing over even a negligible portion of this waste intensity back into valuable power would assist with guaranteeing a sustainable energy supply and reducing fossil fuel byproducts.

“The U.K. is anticipated to require two times as much power in 2050 as it did in 2020. The capability of thermoelectric innovation has been known about for various years; however, presently, generators are costly and not exceptionally proficient. Utilizing new thermoelectric innovation that is less expensive to run and more productive could help turn the 48 TWh of waste intensity the U.K. creates consistently into power and could help us on the way to arrive at net zero.”

Watches and vehicles

Besides the fact that advancements could have positive ramifications for the battle against environmental change, they could likewise have an effect on a portion of the gadgets and hardware we utilize day to day.

As of now, thermoelectric gadgets and generators are costly and only utilized in specialty applications (for example, the Explorer tests sent by NASA to investigate space past the nearby planet group). In any case, the improvement of new thermoelectric generators could hugely affect wearable gadgets, for example, savvy watches, where the flow innovation depends on batteries that require customary re-energizing. Dispensing with this prerequisite, by gathering body intensity to create power, couldn’t be more advantageous yet additionally make wearable technology more solid in basic applications, like observing the strength of defenseless or older patients.

The improvement could be useful for the engine business, permitting carmakers to foster thermoelectric generators that utilize squandering intensity to charge the batteries of module electric or crossover vehicles, expanding their proficiency. Production lines delivering glass, steel, or concrete, which are right now carbon-escalated and create a lot of waste intensity, could likewise profit from the innovation.

More information: Shriparna Mukherjee et al, Beyond Rattling: Tetrahedrites as Incipient Ionic Conductors, Advanced Materials (2023). DOI: 10.1002/adma.202306088