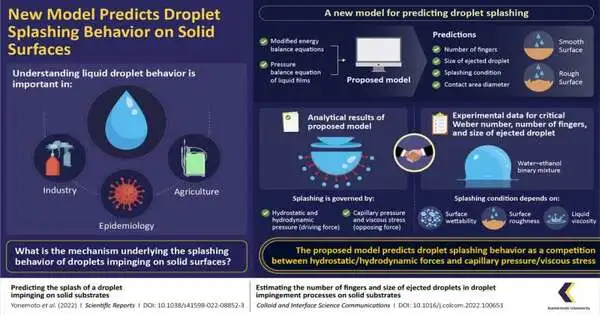

The investigation of fluid beads and their way of behaving upon impingement is vital in many fields, including farming, designing, and medication. Drop conduct expectation has applications in splash painting and pesticide showers, inkjet printing innovation, and spray age during precipitation.A more profound understanding of this peculiarity is, hence, essential not just for propelling our insight into liquid physical science but also innovation.

In such a manner, an especially charming peculiarity is the sprinkling of beads after hitting strong surfaces. A few examinations on fluid film conduct have helped reveal insights into drop sprinkling. In any case, no agreement has arisen in regards to when a drop can be anticipated to sprinkle. Besides, wetting conduct, or the simplicity with which a fluid sticks to smooth and harsh surfaces, is similarly vital to comprehend.

In the meantime, a gathering of researchers from Japan and China has recently led a review to resolve this issue. The examination group, led by Associate Professor Yukihiro Yonemoto from Kumamoto University, Japan as a team with Professor Tomoaki Kunugi from Zhejiang University, China, has proposed another model that can foresee when a bead will sprinkle subsequent to impinging on a strong surface. Their examination was distributed in Scientific Reports and Colloid and Interface Science Communications.

At the point when a bead slams into a strong surface, a shaky fluid film shows up underneath the encroached drop. To represent this shakiness, the group changed the energy balance condition that predicts the spreading contact region for smooth and harsh surfaces.

“Our findings could open the way for a better understanding of the fundamental physics of rim or liquid film disintegration, as well as find applications in crucial technical disciplines such as printing, coating, and spraying,”

Dr. Yonemoto.

To foster the hypothetical model for anticipating the sprinkling condition, the group considered the strain equilibrium of the fluid film. The logical outcomes got from joining the changed energy balance condition and the strain balance condition were in great concurrence with the basic Weber number (a dimensionless amount that portrays liquid stream on surfaces) for sprinkling got tentatively for water-ethanol blend fluid drops.

The outcomes showed that the sprinkling condition didn’t rely upon the thickness of the fluid alone, but in addition on the wettability and harshness of the strong surface. Besides, the sprinkling rule was represented by a rivalry between hydrostatic and hydrodynamic tensions, which were the main thrusts, and fine strain and gooey pressure, which were the restricting powers. Sprinkles happened while the main thrusts won out.

As well as foreseeing the sprinkling conditions, the sprinkling model additionally anticipated the size of the dispersed optional drops and the quantity of finger-like fluid designs that showed up once the fluid film weakened. The model showed that the thickness of the fluid film, which emerged after the drop impingement, was connected with the size of the optional drops. Further, the size of these optional drops and the quantity of fingers were connected together. They were likewise impacted by the wettability and surface harshness of the strong surface, notwithstanding the fluid properties.

“Our outcomes could prepare for a superior understanding of the essential material science of edge or fluid film fracture as well as find applications in significant designing fields connected with printing, covering, and showering,” says Dr. Yonemoto.

More information: Yukihiro Yonemoto et al, Predicting the splash of a droplet impinging on solid substrates, Scientific Reports (2022). DOI: 10.1038/s41598-022-08852-3

Yukihiro Yonemoto et al, Estimating the number of fingers and size of ejected droplets in droplet impingement processes on solid substrates, Colloid and Interface Science Communications (2022). DOI: 10.1016/j.colcom.2022.100651