Self-healing is gaining popularity as a technology for autonomously addressing the effects of damage in composite materials. Inside cracks in structural composites are difficult to detect and repair. As a result, active polymeric materials with self-healing functionality are gaining popularity because they represent a new paradigm for structural materials that require long-term durability and reliability.

Researchers developed a new type of carbon fiber reinforced material that is as strong and light as conventional materials but can be repeatedly healed with heat, reversing any fatigue damage. This also allows it to be broken down and recycled when it reaches the end of its useful life.

Carbon-fiber-based composite materials are gradually replacing metals in the advancement of all kinds of products and applications, from airplanes to wind turbines to golf clubs, due to their high strength and lightweight. However, there is a cost. The most commonly used carbon fiber materials are nearly impossible to repair or recycle once they have been damaged or compromised.

Developing fatigue-resistant composites is a major need in the manufacturing community. In this paper, we show how traditional heat sources or radiofrequency heating can be used to indefinitely reverse and postpone the aging process of a material.

Aniruddh Vashisth, University of Washington

A team of researchers describes a new type of carbon fiber reinforced material that is as strong and light as traditionally used materials but can be repeatedly healed with heat, reversing any fatigue damage, in a paper published in the journal Carbon. This also allows it to be broken down and recycled when it reaches the end of its useful life.

“Developing fatigue-resistant composites is a major need in the manufacturing community,” said co-lead author Aniruddh Vashisth, an assistant professor of mechanical engineering at the University of Washington. “In this paper, we show how traditional heat sources or radiofrequency heating can be used to indefinitely reverse and postpone the aging process of a material.”

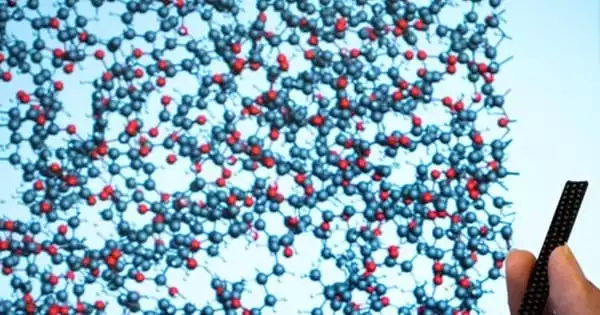

The material is part of a new class of materials known as carbon fiber reinforced vitrimers, which are named after the Latin word for glass and exhibit a combination of solid and fluid properties. Carbon fiber reinforced polymers are the most common materials used today, whether in sporting goods or aerospace. Finally, healing agent polymerization occurs as a result of contact with embedded hardeners to bond cracks. The imidazoline derivatives curing agent used in this study is a latent curing agent that can be well dispersed in the epoxy matrix during composite manufacturing. The microcapsules used in the binary healing system are made in situ by polymerizing urea and formaldehyde in an oil-in-water emulsion.

Traditional carbon fiber reinforced polymers are classified into two types: thermoset and thermoplastic. The “set” variety includes epoxy, a glue-like material in which the chemical bonds that hold it together harden permanently. The “plastic” version contains a softer type of glue that allows it to be melted down and reworked, but this is a disadvantage for high strength and stiffness. Vitrimers, on the other hand, can link, unlink, and relink, allowing them to act as a bridge between the two.

“Consider each of these materials to be a room full of people,” Vashisth said. “Everyone in the thermoset room is holding hands and refusing to let go. People are shaking hands and moving around in the thermoplastic room. People shake hands with their neighbors in the vitrimer room, but they have the ability to exchange handshakes and make new neighbors so that the total number of interconnections remains constant. This reconnection is how the material is repaired, and this is the first paper to use atomic-scale simulations to understand the underlying mechanisms for those chemical handshakes.”

The research team believes that vitrimers could be a viable alternative for many products currently made from thermosets, which is desperately needed because thermoset composites have begun to pile up in landfills. According to the researchers, healable vitrimers would represent a significant shift toward a dynamic material with a different set of considerations in terms of life-cycle cost, reliability, safety, and maintenance.

“These materials have the potential to convert the linear life cycle of plastics to a circular life cycle, which would be a significant step toward sustainability,” said co-senior author Nikhil Koratkar, professor of mechanical, aerospace, and nuclear engineering at Rensselaer Polytechnic Institute.