Couple sun-powered cells in light of perovskite semiconductors convert daylight into power more productively than traditional silicon-based solar cells. To prepare this innovation for the market, further upgrades concerning its soundness are expected to be made.

Specialists of the Karlsruhe Establishment of Innovation (Pack) and of two Helmholtz stages—Helmholtz Imaging at the German Disease Exploration Center (DKFZ) and Helmholtz computer-based intelligence—have prevailed with regards to figuring out how to anticipate the nature of the perovskite layers and subsequently that of the subsequent sun-oriented cells. With the help of AI and new strategies in man-made brainpower (man-made intelligence), it is feasible to evaluate their quality from varieties in light emanation currently in the assembling system.

The outcomes, which can be utilized to determine better assembly processes, have been distributed in cutting-edge materials.

“One of the most difficult challenges is producing these high-grade, multi-crystalline thin layers with no flaws or holes using low-cost and scalable methods.”

professor Ulrich W. Paetzold who conducts research at the Institute of Microstructure Technology and the Light Technology Institute of KIT.

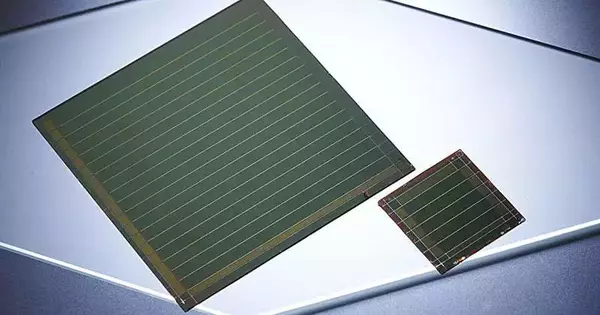

Perovskite-paired sun-powered cells join a perovskite sun-oriented cell with a regular sun-powered cell, for instance, in light of silicon. These cells are viewed as a cutting-edge innovation. They boast a productivity of over 33%, which is a lot higher than that of traditional silicon-sun-oriented cells. In addition, they utilize modest, unrefined components and are effortlessly fabricated. To accomplish this degree of effectiveness, a very thin, high-grade perovskite layer, whose thickness is just a small part of that of human hair, must be created.

“Fabricating these high-grade, multi-glasslike slim layers with no lacks or openings utilizing minimal expense and adaptable techniques is perhaps the greatest test,” says residency track teacher Ulrich W. Paetzold, who conducts research at the Foundation of Microstructure Innovation and the Light Innovation Organization of Pack.

Significantly, under clearly wonderful lab conditions, there might be obscure variables that cause variations in semiconductor layer quality. “This disadvantage ultimately forestalls a speedy beginning of the modern-scale creation of these profoundly proficient sun-oriented cells, which are required so seriously for the energy circle to return.”

Computer-based intelligence tracks down secret indications of powerful covering.

To find the variables that impact covering, an interdisciplinary group comprising of the perovskite sun-based cell specialists of Unit has combined efforts with experts for AI and Logical Man-made Brainpower (XAI) of Helmholtz Imaging and Helmholtz computer-based intelligence at the DKFZ in Heidelberg. The specialists created simulated intelligence techniques that train and dissect brain networks, utilizing a tremendous dataset. This dataset incorporates video accounts that show the photoluminescence of the thin perovskite layers during the assembly process.

Photoluminescence alludes to the brilliant discharge of the semiconductor layers that have been invigorated by an outside light source. “Since even specialists couldn’t see anything specific on the flimsy layers, the thought was destined to prepare a computer-based intelligence framework for AI (profound figuring out how) to recognize concealed indications of good or unfortunate covering from the large numbers of information things on the recordings,” Lukas Klein and Sebastian Ziegler from Helmholtz Imaging at the DKFZ make sense of.

To channel and investigate the generally dispersed signs yielded by the Profound Learning simulated intelligence framework, the specialists thusly depended on techniques for logical, man-made reasoning.

A plan for follow-up research

The scientists found out tentatively that the photoluminescence shifts during creation and that this peculiarity affects the covering quality. “Key to our work was the designated utilization of XAI techniques to see which elements must be changed to get a high-grade sun-powered cell,” Klein and Ziegler say.

This isn’t the standard methodology. As a rule, XAI is just utilized as a sort of guardrail to keep away from botches while building man-made intelligence models. “This is a difference in worldview: Acquiring profoundly pertinent bits of knowledge in materials science in such a precise way is an absolutely new encounter.”

It was for sure the end drawn from the photoluminescence variety that empowered the specialists to make the following stride. After the brain networks had been prepared in like manner, the computer-based intelligence had the option to foresee whether each sun-powered cell would accomplish a low or elevated degree of effectiveness in view of which variety of light outflow happened when in the assembly system.

“These are very interesting outcomes,” says Ulrich W. Paetzold. “Because of the consolidated utilization of artificial intelligence, we have a strong hint and know which boundaries should be changed in any case to further develop creation. Presently, we can conduct our tests in a more designated manner and are not generally compelled to look blindfolded for the difficult-to-find little item. This is an outline for follow-up research that likewise applies to numerous different parts of energy exploration and materials science.”

More information: Lukas Klein et al, Discovering Process Dynamics for Scalable Perovskite Solar Cell Manufacturing with Explainable AI, Advanced Materials (2023). DOI: 10.1002/adma.202307160