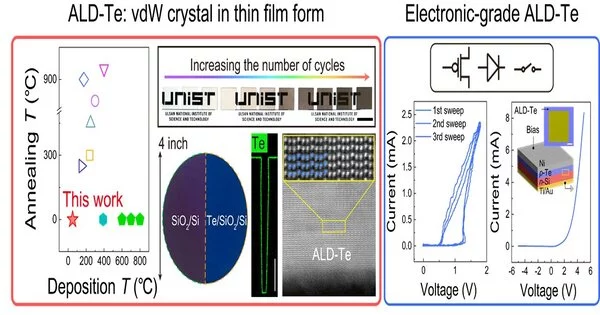

An exploration group, led by Teacher Joonki Suh in the Branch of Materials Science and Designing and the Doctoral-level College of Semiconductor Materials and Gadgets Designing at UNIST, has made a huge leap in slender film statement innovation. By utilizing an inventive nuclear layer statement (ALD) process, teacher website optimization effectively accomplished the customary course of action of tellurium (Te) particles at low temperatures as low as 50 degrees Celsius.

The ALD technique is a state-of-the art slim film process that empowers exact stacking of semiconductor materials at the nuclear layer level on three-layered structures—even at low interaction temperatures. In any case, conventional application to cutting-edge semiconductors requires high handling temperatures over 250 degrees Celsius and extra-intensity therapy exceeding 450 degrees Celsius.

In this exploration, the UNIST group applied ALD to monoelemental van der Waals tellurium, a material under broad examination for its expected applications in electronic gadgets and thermoelectric materials.

“This study meets all of the critical criteria for low-temperature, large-area, and high-quality synthesis in semiconductor deposition processes,”

Professor Joonki Suh in the Department of Materials Science and Engineering.

Amazingly, they effectively manufactured great Te slender movies with practically no post-statement heat treatment at an exceptionally low temperature of just 50 degrees Celsius. The subsequent movies showed uncommon consistency with exactly controlled thickness down to the nanometer scale, accomplishing a wonderful molecule plan with one out of every billion particles.

To upgrade reactivity at lower temperatures, the exploration group utilized two antecedents with corrosive base properties. Furthermore, they acquainted co-reactants with work on surface responses and strength while embracing a continuing dosing strategy by infusing forerunners in more limited spans. These procedures empowered the creation of thick and nonstop Te dainty movies, in contrast with regular strategies that frequently brought about permeable or irregular grain statements.

The created fabricating process took into account wafer-scale development on whole 4-inch (100mm) wafers, giving exact nuclear layer-level thickness control and a uniform affidavit. Besides, the Te Slim movies exhibited similarity with vertical, three-layered structures—a critical prerequisite for high gadget coordination. This leading edge holds huge potential for different electronic gadgets like semiconductors, rectifiers, and other components.

“This examination satisfies every one of the fundamental measures of low temperature, huge region, and excellent blend in semiconductor affidavit processes,” expressed Teacher Suh.

The consequences of this examination were distributed in ACS Nano.

More information: Changhwan Kim et al, Atomic Layer Deposition Route to Scalable, Electronic-Grade van der Waals Te Thin Films, ACS Nano (2023). DOI: 10.1021/acsnano.3c03559