Pressing sufficient energy into a battery to control a vehicle is coming down on the capacity of gadgets that, for the last 100 years or thereabouts, have mostly been entrusted with running little apparatuses and hardware. The pressure is getting to them—as shown in breakdowns, decreased execution, and even implosions. Analysts at Drexel University are attempting to help by taking a portion of the exacting intensity off batteries and plotting a more reasonable course for their utilization in electric vehicles.

“One of the major roadblocks to the development of electric vehicles and, as a result, their market share expansion is the low specific energy of batteries, which makes EVs overweight, especially for long-range designs,”

Drexel’s Ahmad Najafi, Ph.D., an assistant professor in the College of Engineering,

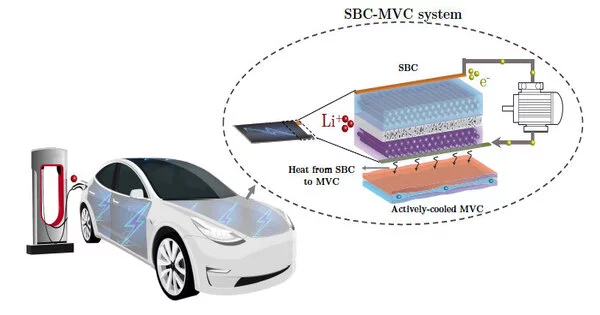

In an as of late distributed paper in the journal Composites Part B: Engineering, analysts driven by Drexel’s Ahmad Najafi, Ph.D., an associate professor in the College of Engineering, uncovered a plan enhancement framework for integrating a vein-like cooling network into the bundling of another age of carbon-fiber based batteries utilized in electric vehicles. Their technique adjusts execution-improving variables, similar to battery limit and conductivity, against dangerous factors, including weight and warm action, that can drain execution and prompt glitches, to give the best battery bundle details for any electric vehicle plan.

“One of the essential obstructing factors in the improvement of EVs, and therefore growing their portion of the overall industry, is that the particular energy of batteries is low, which makes EVs heavy, particularly for a long-range plan,” the creators composed.

Image Credit: Drexel University

Complex batteries

Indeed, even as interest in electric vehicles has grown in response to growing concerns about air quality and climate change, as well as rising gas prices, the market has been tempered by a slew of high-profile electric vehicle reviews in the last year that have called the durability and safety of their batteries into question.

As a result, more organizations are investigating the use of strong batteries—a slim, carbon fiber-based variant of the larger lithium-particle batteries widely used in electric vehicles—on the grounds that they can be cleverly integrated into the actual design of the vehicle body as a method of reducing weight.

According to some estimates, reducing the weight of a vehicle by 10% can increase its mileage productivity between charges by up to 6-8%, so replacing parts of the vehicle outline with a carbon-fiber composite that functions both as a primary part and as a battery could lessen the overall load of the vehicle while also expanding its energy stockpiling limit.

Warming up

For these underlying, or “mass-less,” batteries to succeed, they must stand up to a test that emerges from their utilization of a strong polymer—instead of a fluid electrolyte arrangement—as their vehicle for electron travel.

Najafi explained, “Heat age will be significantly higher in underlying batteries in comparison with standard lithium-particle batteries.” The reason for this is that the conductivity of the polymer electrolyte is a lot more modest than that of the fluid electrolytes utilized in lithium-particle batteries. This implies that electrons face a bottleneck as they travel through the polymer; they’re compelled to move increasingly slowly, an outcome producing more intensity as the battery releases its energy.

“While underlying battery composites are a promising innovation for lessening weight in electrical vehicles, their plan could positively profit from the expansion of a warm administration framework,” Najafi said. “In addition to the fact that this could improve the scope of the EV, it would likewise extraordinarily lessen the possibility of a warm out of control response.”

Remaining cool

Najafi’s examination group has been creating extraordinary composite materials for heat executives for various years. Their work draws on nature’s own cooling strategy — the vascular framework — to disseminate heat. Adjusting a planning apparatus they developed to plot the ideal “microvascular” network, the analysts had the option to configure cooling composites that would fill in as a feature of the primary battery bundling presently being tried by organizations like Tesla, Volvo, and Volkswagen.

The plan framework, introduced by Najafi’s group in their most recent exploration, can compute the best example size and number of microvascular channels to rapidly disseminate heat from the batteries, as well as enhance the plan for stream proficiency of the coolant traveling through the channels.

“These composites work something like a radiator in a gas-powered motor vehicle,” Najafi said. “The coolant attracts the intensity and pulls it away from the battery composite as it travels through the organization of microchannels.”

Sandwiching the underlying batteries between layers of cooling microvascular composites can balance out their temperature during use and expand the time and power range in which they can work.

The right fit

As revealed in the paper, the group’s underlying battery enhancement process thinks about a few plan boundaries, for example, thickness and fiber headings in each layer of carbon fiber; volume part of filaments in the dynamic materials; and the number of microvascular composite boards expected for warm guidelines.

To test every blend, the group estimated the firmness of each primary battery-cooling composite cover, to guarantee they fulfilled the vehicle’s underlying trustworthiness guidelines. Then they mimicked the energy interest of a vehicle at different velocities over a length of a few minutes, while recording the temperature of the battery and the anticipated scope of the vehicle.

As per the examination, PC models of one streamlined framework demonstrated the way that it could work on the driving scope of a Tesla model S by as much as 23%. Yet, the group noticed that the genuine value of their work is its capacity to gather the best blend of battery size and weight—including sufficient cooling ability to keep it working—for any electric vehicle underway now and any future plans.

“While we realize that all this weight loss can assist with working on the exhibition of an EV, warm administration can be just as significant — maybe more, with regards to causing individuals to feel open to driving them,” Najafi said. “Our framework endeavors to coordinate upgrades in both of these areas, which could play a significant part in the advancement of electric vehicles.”