Ethylene is once in a while called the main substance in the petrochemical business since it fills in as the feedstock for an enormous range of ordinary items. It’s utilized to deliver radiator fluid, vinyl, manufactured elastic, froth protection, and plastics, everything being equal.

Right now, ethylene is delivered through an energy- and asset-concentrated process called steam breaking, where limits of temperature and tension produce ethylene from unrefined petroleum within the sight of steam and, simultaneously, emanate lots of carbon dioxide into the air.

One more manner in which ethylene can be created, in any case, is through a cycle called oxidative coupling of methane (OCM). It can possibly be a greener choice than steam breaking, yet up to this point, how much ethylene it yields didn’t make the interaction financially practical.

“The idea behind chemical looping is that instead of feeding methane and oxygen into the chamber with the catalyst at the same time, you do it consecutively.”

Mosevitzky Lis, who is also one of the study’s co-authors.

“Up to this point, the synergist yield has been underneath 30% for a solitary pass, meaning simply passing the methane and oxygen through the impetus and getting ethylene on the opposite side,” says Bar Mosevitzky Lis, a postdoctoral examination partner in the Branch of Substance and Biomolecular Designing in Lehigh College’s P.C. Rossin School of Designing and Applied Science.

“Concentrates that have reproduced the whole modern cycle utilizing OCM have shown that the innovation doesn’t become beneficial until the single-pass yield comes to somewhere in the range of 30 and 35%.”

OCM is currently one bit closer to leaving the lab and entering this present reality. Interestingly, scientists at North Carolina State College (NCSU) and Lehigh College, in a joint effort with specialists from the Guangzhou Establishment of Energy Transformation and the East China College of Science and Innovation, have fostered an OCM impetus that surpasses 30% with regards to the development of ethylene.

The paper depicting their advancement was, as of late, distributed in Nature Correspondences.

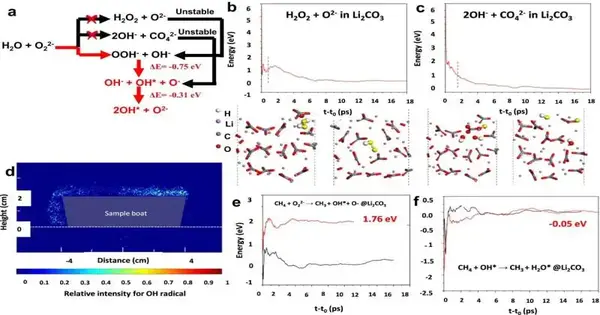

The joint effort was driven by Fanxing Li, Alcoa Teacher of Designing at NCSU. His group fostered a class of center-shell Li2CO3-covered blended uncommon earth oxides as impetuses for the oxidative coupling of methane utilizing a synthetic circling plan. The outcome was a solitary pass yield of up to 30.6%.

“The thought with substance circling is that, as opposed to doing a co-feed of methane and oxygen into the chamber with the impetus, you do it successively,” says Mosevitzky Lis, who is likewise one of the review’s co-creators.

“Over the long haul, you lose oxygen from the impetus, and it becomes insufficient. With synthetic circling, you start with methane, then change to oxygen, then back to methane, and the oxygen serves to constantly reoxidize the impetus, in this manner renewing its capacity to give oxygen to the response.”

Mosevitzky Lis and his group at Lehigh—led by Israel Wachs, G. Whitney Snyder, Teacher of Synthetic and Biomolecular Designing and Overseer of the Operando Sub-atomic Spectroscopy and Catalysis Exploration Lab—did the portrayal of the impetus.

“Our specialization is in situ surface portrayal,” says Mosevitzky Lis, “meaning we describe the outer layer of impetuses while the response is running. We apply a wide exhibit of physical and substance strategies to comprehend the changes impetuses go through while the synergist response runs on their surface and how these changes connect with what makes them such great impetuses.”

He says the impetus is made out of a blended oxide center covered by lithium carbonate, and the cooperation between the center and the shell during compound circling is responsible for the high return. The outcomes really intend that, interestingly, updating methane—which can be tracked down in flammable gas and biogas—into ethylene could be accessible for industry.

“OCM can possibly be less expensive and more productive with regards to energy and outflows,” he says. “In addition, rather than utilizing raw petroleum, you’re utilizing methane, which regularly comes from flammable gas but may likewise be produced in the future from biogas and the electrochemical decrease of carbon dioxide. What’s more, when you have ethylene, you’re ready to change it into endless items that are utilized by the entire world.”

The subsequent stage is to decide the appropriateness of the impetus for modern-scale creation while attempting to push the yield considerably further up. For the time being, nonetheless, having at last improved on a technique that has remained an unfulfilled commitment since the 1980s marks an achievement.

“The multifaceted design of the framework and the elements that occur are practically similar to craftsmanship,” says Mosevitzky Lis. “Both the center and the shell of the impetus go through exceptionally outrageous cycles, producing a wide range of fascinating things on a superficial level. It’s lovely.”

More information: Kun Zhao et al, Lithium carbonate-promoted mixed rare earth oxides as a generalized strategy for oxidative coupling of methane with exceptional yields, Nature Communications (2023). DOI: 10.1038/s41467-023-43682-5