Photonic thermometers, which measure temperature using light, can possibly reform temperature estimation by being quicker, more modest, and stronger than conventional thermometers. Generally, the sensors work by passing light into a design that is sensitive to temperature. The light that emerges from the gadget gives researchers data about the temperature at which the sensor was uncovered.

Sometime in the not-so-distant future, these little thermometers—and extra kinds of photonic sensors, which measure strain, stickiness, speed increase, and different amounts—could be implanted into designs, for example, structures or scaffolds as they are constructed. By estimating these properties as concrete sets, photonic sensors could give engineers significant data about how the construction has shaped, which can assist them with projecting how the design will perform in the long haul.

However, one issue analysts haven’t yet addressed is the most ideal way to “grill” these photonic sensors—that is, to place light in and get light out. Customary strategies, which include utilizing lasers to make every recurrence of light that enters the sensor, are troublesome, slow, costly, and massive.

Presently, scientists at the Public Establishment of Guidelines and Innovation (NIST) have planned and tried a method for examining these sensors somewhere in the range of 10 and multiple times quicker than past strategies. They do this with what many refer to as a double recurrence brush framework, utilized in the past for errands, for example, estimating follow-up measures of ozone-depleting substances, but up until recently never utilized with photonic thermometers.

The paper is distributed in the journal Optics Letters, and the rule-of-thumb try makes them a stride closer to commercializing this innovation.

“I was astounded by how well it functioned,” said NIST’s Zeeshan Ahmed.

An extra advantage is that, unlike conventional strategies for getting light into and out of the sensors, the double brush framework could uphold various photonic sensors immediately, further lessening the size and cost of a future popularized framework.

Twenty inquiries

To utilize a photonic thermometer, scientists put light of numerous frequencies into a fiber-optic link. That light connects with a sensor or some likeness thereof—for this situation, a kind of grinding comprising a progression of engraving marks inside the fiber.

The way that the light collaborates with the grinding depends on the temperature. The sign specialists return from openness to a temperature is a decline in the sufficiency—basically, a plunge—in the light from one of the numerous frequencies they put into the fiber. The frequency that has the plunge in it lets them know which temperature the sensor is encountering.

Yet, how would you get the various frequencies of light into the fiber?

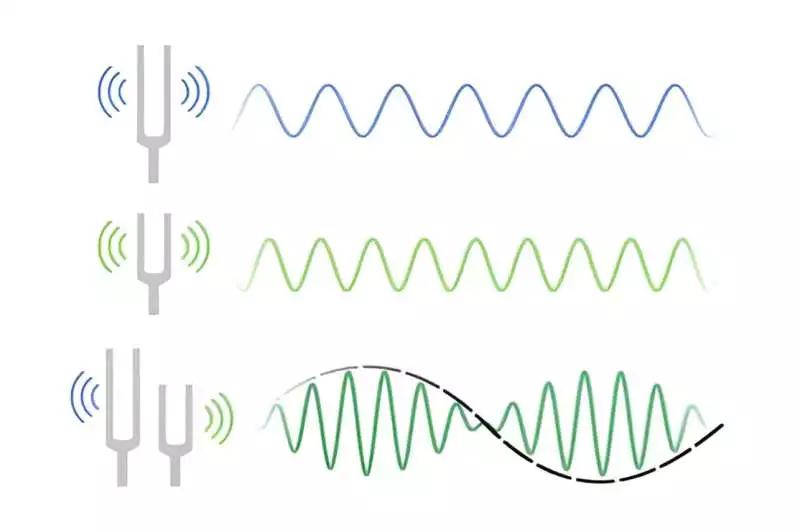

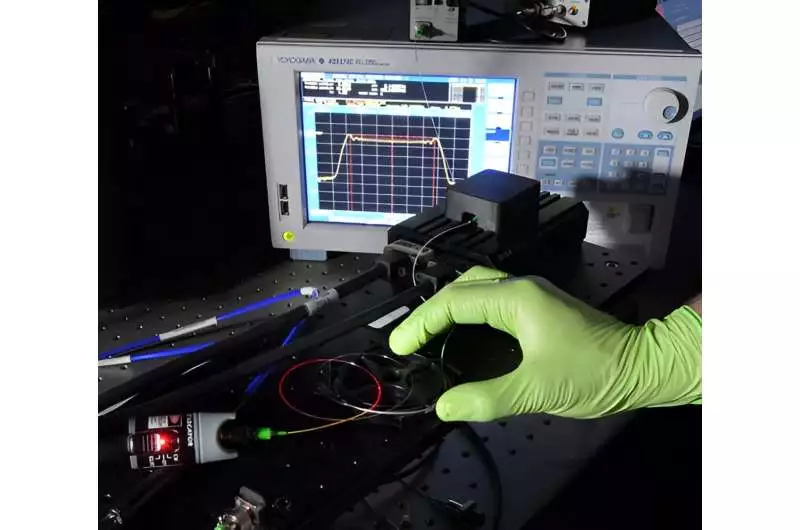

Red laser light (for showing purposes) in a fiber optic link. The photonic thermometer sensor sits inside the finish of a link like this one. Credit: Jennifer Lauren Lee/NIST Exhibit of a “beat” design with two tuning forks that are practically indistinguishable but somewhat off from one another in tone. In the event that you play them simultaneously, the tones will disrupt one another and make a beating, while the sound gets, on the other hand, clear and delicate. Credit: Sean Kelley/NIST

One customary way is by “clearing” the laser, making a progression of various frequencies, each in turn, and sending every one into the sensor. To keep up with precision, scientists should take the extra step of contrasting every frequency with a standard that confirms that the frequency they are creating is the one they planned.

“This is a sluggish approach to getting things done,” Ahmed said. “It’s a piece like playing Twenty Inquiries: You ask the sensor, is this frequency the one with the dunk in it? No. What about this one? No.”

Speed is especially an issue for applications where the temperatures are changing quickly—for instance, while estimating microsecond (millionth of a second) temperature changes because of a radiation portion in radiation treatment, a kind of malignant growth therapy that utilizes light emissions to warm up and kill disease cells.

“The conventional approaches to doing the examination are not undeniably appropriate for estimating quick changes in temperature,” Ahmed said. “We can make it work, yet at the same time, it’s noticeably flawed. Anyway, where our group and I began talking was in that setting of, How might we in all actuality do super quick estimations yet do them precisely?”

Searching through the potential outcomes

In the ongoing task, the group achieved this objective utilizing gadgets called recurrence brushes—laser light comprising a progression of various frequencies, each similarly divided from the others. Frequency and recurrence are connected with one another, kind of cut out of the same cloth. (The more limited the frequency, the higher the recurrence, as well as the other way around.) While reviewing these frequencies plotted on a diagram, recurrence brushes seem to be like hair brushes, where every tooth is a discrete frequency of light.

Searches can be utilized for a wide range of things, from building nuclear clocks to going about as a source of perspective, or a kind of ruler, for light that researchers can use to gauge a light sign emerging from their trial.

In this work, the scientists utilize one sort of brush as a wellspring of light—what they allude to as a “cross examiner—that they ship into the photonic thermometer. The sign scientists are searching for is a lessening in the amount of light from a bunch of teeth relating to a specific temperature.

However, it’s more convoluted than that, since this framework really utilizes not one but two recurrence brushes.

The photonic thermometer expects close infrared light with frequencies between around 1,520 nanometers (billionths of a meter) and 1,560 nanometers—somewhat excessively lengthy so that natural eyes might be able to see. (For setting, noticeable light has frequencies between around 400 and 800 nanometers.) When the teeth of the brush are so firmly divided—just thousandths of billionths of a meter of contrast between contiguous teeth—seeing the trademark plunge that tells scientists the temperature of the sensor is hard.

To peruse the sign all the more effectively, the scientists make a second brush that is very nearly a precise duplicate of the first—nearly, yet not exactly. Analysts then join the light from the two brushes and send it into the sensor.

Red laser light (for showing purposes) in a fiber optic link. The photonic thermometer sensor sits inside the finish of a link like this one. Credit: Jennifer Lauren Lee/NIST

At the point when the light from the two brushes is consolidated, their marginally counterbalanced frequencies make a beat. Imagine you have two tuning forks creating tones that are practically indistinguishable but somewhat off from one another. Assuming you play them consistently, they could sound similar to you. In any case, on the off chance that you play them together, their marginally various sounds slow each other down. You can really hear this distinction—it seems like a beat, with the tone getting stronger and milder and stronger and gentler.

The sum by which the two brushes’ teeth are counterbalanced from one another is in the system of radio recurrence (RF) waves, light with frequencies on the request for meters. By utilizing two optical brushes, the specialists really make a solitary RF brush. The distinction in frequency between each set of teeth in the optical brushes is novel, and that distinction makes every tooth in the RF brush exceptional.

Significantly, the “plunge” in frequency in the optical system, which lets specialists know the temperature the sensor is encountering, likewise results in a “plunge” in the RF yield. That makes the drop in sufficiency for a specific frequency more observable.

“That is the benefit of the double brush approach: It packs all of that optical data into the RF system, where it’s simpler to peruse out,” said NIST’s A.J. Fleisher.

That is a Kelvin of an alternate tone.

To test how well their new plan functioned, the NIST group needed to expose their sensor to a very controlled temperature. In this way, while being questioned by the laser light from the two optical recurrence brushes, the photonic sensor itself sits in a bottle-like holder called a fixed-point cell.

Fixed-point cells are lumps of unadulterated material that are either dissolving or freezing. While they’re going through that stage change, the temperature within them is steady and notable. Fixed-point cells are utilized to acknowledge temperature as indicated by the global arrangement of units, or SI—the authority worldwide temperature scale.

“We utilized a fixed-point cell since we needed temperature soundness not to be the restricting component in this examination,” said NIST’s Tobias Herman. “Like that, on the off chance that something was moving or loud, we could exclude the temperature shower as the source. It was only there to be a phase on which the investigative specialist could sparkle.”

With this arrangement, they had the option to quantify temperature to within ten thousandths of a kelvin, which the scientists say is adequate for most modern applications.

“It was really astonishing,” Herman said. “I utilized a comparative fiber when we were firing up an alternate examination program, and I was clearing the laser, a conventional method of cross-examination, and the rate at which I was getting information was cripplingly slow. Conversely, the procurement rate [data assortment time] of this framework was astounding to me. Be that as it may, truth be told, I’m a temperature master, not a brush master. This isn’t my field, so I was prepared for bewilderment.”

Before long, the specialists desire to attempt a similar arrangement with more than one sensor in turn. That is the commitment of the double-brush photonic framework: having the option to have numerous thermometers as well as other photonic sensors in series, with a similar laser light going through every one.

“It’s exceptionally near what we want it to be for commercialization,” Ahmed said. “We previously met a ton of the measurements we really want to meet, similar to the exactness and speed of the estimations. This study demonstrates the way that you can take a little rendition of a double brush framework and find sufficient solutions for the application space you really want.”

More information: Adam J. Fleisher et al, Dual electro-optic frequency comb photonic thermometry, Optics Letters (2023). DOI: 10.1364/OL.482838