Grinding is difficult to foresee and control, particularly since surfaces that come into contact are seldom completely level. New investigations exhibit how much erosion between two silicon surfaces, even at large, is still up in the air from the shaping and cracking of minuscule compound connections between them. This makes it conceivable to control how much contact is made using surface science procedures. This examination has been distributed in actual audit letters.

“There is an absence of quantitative comprehension of grinding, regardless of its critical job in handling difficulties as different as foreseeing tremors and decreasing energy utilization in mechanical gadgets,” says Ph.D. analyst Liang Peng, who led the exploration project. This is no small matter. Rubbing is assessed to be responsible for over 20% of our worldwide energy utilization. Controlling grating in apparatus is additionally significant for diminishing material wear and expanding positioning accuracy.

Peng cooperated with different specialists of the Establishment of Physical Science and the Van ‘t Hoff Foundation of Sub-atomic Sciences at the College of Amsterdam, as well as the High-Level Exploration Community for Nanolithography (ARCNL). The examination is essential for a continuous, coordinated effort to explore how huge scope grating arises at an infinitesimal level.

“Despite its critical role in tackling challenges such as earthquake prediction and reducing energy consumption in mechanical devices, there is a lack of quantitative understanding of friction.”

Ph.D. researcher Liang Peng, who conducted the research project.

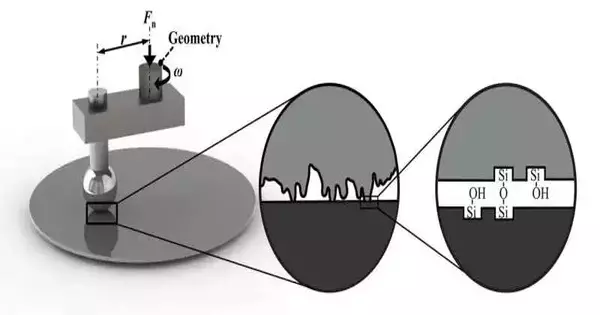

Lately, new exploration strategies have permitted analysts to focus on what precisely happens when two surfaces connect and slide more than each other. Urgently, surfaces are rarely completely smooth. At the size of a nanometer, one-billionth the size of a meter, they seem to be precipitous scenes with articulated pinnacles and valleys.

Past examinations and mathematical reproductions have exhibited that, at this limited scale, rubbing is not set in stone by the development and bursting of connections between surface particles. This is impacted not simply by the harshness of the sliding surfaces but additionally by the fact that iotas or particles (like water) are available at the connection point.

“We chose to broaden and apply these nanofriction components to bigger, economically significant scales,” makes sense of Peng. Utilizing a unique instrument called a rheometer, the specialists concentrated on how much contact between a generally unpleasant silicon ball and a smooth silicon wafer relies upon the thickness of infinitesimal substance securities at the connection point. Silicon (Si) is an especially fascinating material to concentrate on because of its wide use in the semiconductor business. Its overflow in the world’s coverage likewise makes it applicable to the investigation of seismic tremors.

Subsequent to cleaning the surfaces of pollutants, the analysts found significantly less power is expected to slide the ball over the wafer—as such, there is less erosion—when the surfaces are dried for longer in unadulterated nitrogen gas. Further investigations showed what occurs at the degree of particles: longer drying lessens the quantity of hydroxyl (goodness) bunches uncovered at the silicon surface. When carried into contact with another silicon surface, the presence of these gatherings brings about the development of silicon-oxygen-silicon (Si-O-Si) connections between the two surfaces.

The exploration shows that there is a striking connection between the grinding force estimated at large scales and the thickness of minute Si-Goodness bunches present on the two silicon surfaces before contact, which controls the quantity of Si-O-Si bonds connected. The thickness of these synthetic bonds is controlled by setting the time allotment for which the cleaned surfaces are dried. Excitingly, this implies that it is feasible to anticipate and control the grinding force between silicon surfaces.

“Our outcome is very striking since it shows a quantitative comprehension of plainly visible rubbing from first standards. Our discoveries can in this manner span the information hole that hampers grasping-based command over grinding,” closes Liang.

More information: Liang Peng et al, Controlling Macroscopic Friction through Interfacial Siloxane Bonding, Physical Review Letters (2023). DOI: 10.1103/PhysRevLett.131.226201