Metal halide perovskites, arrangement processable materials with worthwhile optoelectronic properties, have as of late arisen as reasonable contenders for creating photovoltaic innovation. Late investigations showed metal halide perovskite-based sun-oriented cells (PSCs) with power change efficiencies (PCEs) above 25.8%, which are within the scope of a few sun-based innovations available today.

While these outcomes are promising, existing manufacturing processes for making metal-halide perovskite-based cells are nowhere near great. Specifically, to arrive at PCEs above 25%, these sun-oriented cells so far must be manufactured in dormant (i.e., synthetically idle) air, for example, inside a nitrogen glovebox.

This powerlessness to manufacture profoundly performing metal halide PSCs at surrounding conditions enormously restricts their huge scope creation and sending, as it adds necessities that would essentially expand their manufacture costs. In a paper distributed in Nature Energy, scientists at North China Electric Power College discovered a technique to make metal halide PSCs with PCEs above 25% in the surrounding air.

“While manufacturing perovskite solar cells (PSCs) in ambient air can speed up industrialization, moisture causes severe decomposition of the perovskite layer, limiting device efficiency. We show that locations close vacancy defects absorb water molecules and cause hydration of the perovskite, eventually leading to material deterioration.”

Luyao Yan, Hao Huang and their colleagues wrote in their paper.

“The manufacture of perovskite sun-powered cells (PSCs) in encompassing air can speed up their industrialization,” Luyao Yan, Hao Huang, and their partners wrote in their paper. “In any case, dampness causes serious deterioration of the perovskite layer, restricting gadget productivity. We show that destinations close to opportunity abandon assimilate water atoms and trigger the hydration of the perovskite, in the end prompting the debasement of the material.”

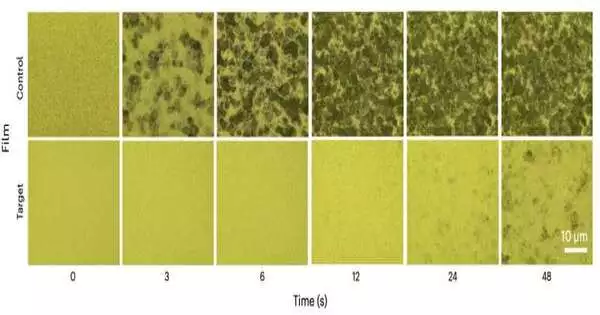

To manufacture their sun-based cells in surrounding cools, Yan, Huang, and their partners obstructed the pathway through which perovskite layers can become hydrated and thus experience extreme harm. They did this utilizing the acetic acid derivation salt type of the substance compound guanabenz, known as GBA.

“Guanabenz acetic acid derivation salt takes out both cation and anion opening, hindering the perovskite hydration and permitting the crystallization of an excellent film in surrounding air,” the scientists wrote in their paper. “With guanabenz acetic acid derivation salt, we get ready PSCs in surrounding air with a confirmed effectiveness of 25.08%.”

In starting tests, the manufacturing system proposed by this group of specialists seemed to yield striking outcomes, empowering the fruitful formation of stable sun-powered cells in view of metal halide perovskites showing economically practical PCEs above 25%. Amazingly, these sun-oriented cells likewise seemed to hold their presentation over the long haul, even in the wake of working in moist conditions.

“The PSCs without epitome keep up with around 96% of their underlying productivity following 2,000 hours of maturing in surrounding air and following 500 hours of working at the most extreme power point under recreated air mass (AM) 1.5 G sun-oriented light in N2 air,” Yan, Huang, and their partners composed. “The epitomized gadgets held 85% of their underlying effectiveness following 300 hours under soggy intensity conditions (85°C and 85% relative stickiness).”

The new work by this group of specialists could add to the future commercialization of metal halide PSCs by opening another road for their minimal expense creation. Later on, the new procedure they concocted could likewise be adjusted and idealized to further improve the presentation of solar-powered cells.

More information: Luyao Yan et al, Fabrication of perovskite solar cells in ambient air by blocking perovskite hydration with guanabenz acetate salt, Nature Energy (2023). DOI: 10.1038/s41560-023-01358-w