A significant number of the most encouraging new drugs showing up in the medication improvement pathway are hydrophobic, essentially—that is, they repulse water—and are subsequently difficult to break up to make them accessible to the body. In any case, presently, scientists at MIT have tracked down a more productive approach to handling and conveying these medications that could make them undeniably more viable.

The new technique, which includes at first handling the medications in a fluid arrangement as opposed to in a strong structure, is accounted for in a paper in the journal Progressed Medical Care Materials, composed by MIT graduate understudy Lucas Attia, late alumni Liang-Hsun Chen, Ph.D., and teacher of compound design Patrick Doyle.

At present, much medication handling is finished through a long series of successive advances, Doyle makes sense of. “We want to smooth out the cycle, yet in addition, get better items, by consolidating these means and utilizing how we might interpret delicate matter and self-gathering processes,” he says.

“We believe that by combining these steps and leveraging our understanding of soft matter and self-assembly processes, we can not only streamline the process but also produce better products.”

Professor of chemical engineering Patrick Doyle,

That’s what Attita adds: “A ton of little particle dynamic fixings are hydrophobic, so they could do without being in water, and they have extremely unfortunate disintegration in water, which prompts their unfortunate bioavailability.” Giving such medications orally, which patients like over infusions, presents genuine difficulties in getting the material into the patient’s circulation system. Up to 90% of the competitor drug particles being created by drug organizations really are hydrophobic, he says, “so this is pertinent to an enormous class of potential medication atoms.”

According to one more benefit of the new cycle, it ought to make it simpler to consolidate various medications into a single pill. “For various sorts of illnesses where you’re consuming different medications simultaneously, this sort of item can be vital in working on quiet consistency,” he adds—just taking one pill rather than a small bunch makes it substantially more possible that patients will stay aware of their prescriptions. “That is really a major issue with these persistent diseases where patients are on exceptionally testing pill systems, so mix items have been displayed to help a ton.”

One key to the new cycle is the utilization of hydrogel—a kind of wipe-like gel material that can hold water and hold particles set up. Present cycles for making hydrophobic materials more bioavailable include precisely crushing the precious stones down to a more modest size, which makes them break up more promptly; however, this interaction adds time and cost to the assembling system, gives little command over the size dissemination of the particles, and can really harm some more fragile medication atoms.

All things considered, the new cycle includes dissolving the medication in a transporter arrangement, then creating little nanodroplets of this transporter scattered all through a polymer arrangement—a material called a nanoemulsion. Then, at that point, this nanoemulsion has just barely gotten through a needle and gelled into a hydrogel. The hydrogel holds the drops set up as the transporter vanishes, abandoning drug nanocrystals. This approach permits exact command over the last precious stone size.

The hydrogel, by keeping the drops set up as they dry, keeps them from essentially combining to form knotty agglomerations of various sizes. Without the hydrogel, the drops would consolidate haphazardly, and “you’d get a wreck,” Doyle says. All things considered, the new interaction leaves a clump of entirely uniform nanoparticles. “That is an extremely extraordinary, novel way that our gathering has designed to do this kind of crystallization and keep up with the nanosize,” he says.

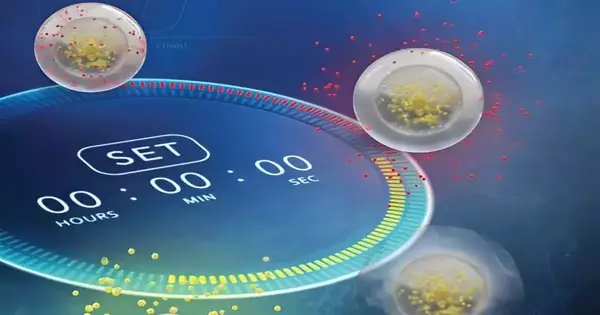

The new interaction yields a two-section bundle: a center, which contains the dynamic particles, encompassed by a shell, likewise made of hydrogel, which has some control over the timing between the ingestion of the pill and the arrival of its items into the body.

“We demonstrated the way that we can oversee the medication discharge, both regarding postponement and rate,” says Doyle, who is the Robert T. Haslam Teacher of Synthetic Designing and Singapore Exploration Teacher. For instance, in the event that a medication is focusing on sickness in the lower digestive system or colon, “we have some control over how long until the medication discharge starts, and afterward we likewise get extremely quick delivery once it starts.” Medications formed the traditional way with mechanical nanomilling, he says, “would have a sluggish medication discharge.”

According to this cycle, Attia “is the principal approach that can shape center shell composite particles and construction drugs in particular polymeric layers in a solitary handling step.”

The following stages in fostering the cycle will be to test the framework on a wide assortment of medication particles, past the two delegate models that were tried up to this point, Doyle says. In spite of the fact that they have motivation to accept that the cycle is generalizable, he says, “the end product speaks for itself—having the information close by.”

The dribbling system they use, he says, “can be versatile; however, there’s a ton of subtleties to be worked out.” But since the materials they are all working with have been picked as ones that are now perceived as safe for clinical use, the endorsement interaction ought to be direct, he says. “It very well may be executed in a couple of years. We’re not stressing over every one of those regular security jumps that I think other novel plans need to go through, which can be extravagant.”

More information: Lucas Attia et al. Orthogonal Gelations to Synthesize Core-Shell Hydrogels Loaded with Nanoemulsion-Templated Drug Nanoparticles for Versatile Oral Drug Delivery, Advanced Healthcare Materials (2023). DOI: 10.1002/adhm.202301667