Scientists from Tokyo Metropolitan University have fostered a method for creating great monolayers of a choice of various transition metal dichalcogenides that meet over a molecularly slim crease. By covering this layer with a particle gel, a combination of an ionic fluid and a polymer, they could energize light outflow along the crease. Because of the adaptable strain across the limit, the light was also observed to be normally circularly energized.Their outcomes are distributed in Advanced Functional Materials.

Light-radiating diodes (LEDs) revolutionarily affect virtually all types of lighting. Yet, as our needs expand and execution requests develop, there is as yet a reasonable requirement for much more power-effective arrangements. One such choice includes the use of in-plane heterostructures, where super thin layers of various materials are designed onto surfaces to create limits. On account of LEDs, this is where electrons and “openings” (portable voids in semiconducting materials) recombine to create light. The materials used, as well as the aspects and nature of the limits, determine the proficiency, usefulness, and extent of application for such designs, which has prompted a lot of research into controlling their construction at the nanoscale.

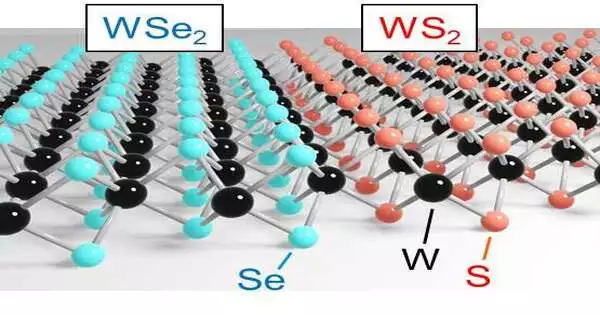

A group of scientists led by Associate Professor Yasumitsu Miyata of Tokyo Metropolitan University, Assistant Professor Jiang Pu, and Professor Taishi Takenobu of Nagoya University have been examining the utilization of a class of materials known as change metal dichalcogenides (TMDCs), a group of substances containing a gathering of 16 components from the occasional table and a progress metal. They have been using a technique known as compound fume testimony to controllably store components onto surfaces to make molecularly thin monolayers; much of their work has been concerned with how such monolayers can be shifted to make designs with various locales made of various TMDCs.

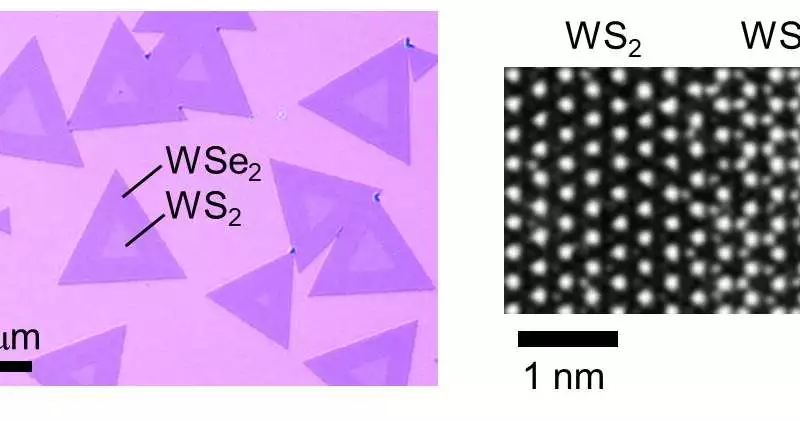

Presently, a similar group has prevailed in essentially refining this innovation. They updated their development chamber so various materials could be drawn nearer to the substrate in a set grouping; they likewise acquainted added substances with changes in the vaporization temperature of every part, considering improved conditions for the development of great glasslike layers.

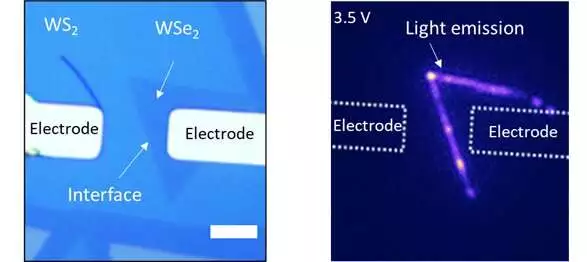

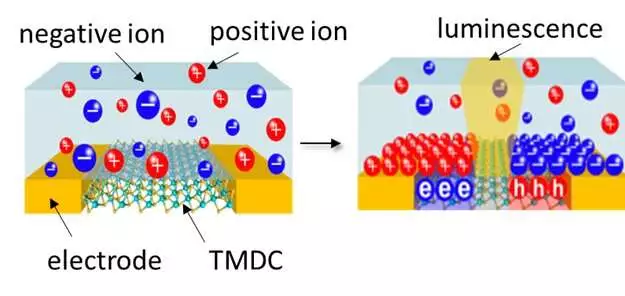

Thus, they prevailed with regard to utilizing four unique TMDCs to make six distinct kinds of sharp, molecularly slim “creases.” Furthermore, by adding a particle gel, a combination of an ionic fluid (a liquid of positive and negative particles at room temperature) and a polymer, a voltage could be applied across the creases to create electroluminescence, similar to the essential peculiarity of basic LEDs. The adaptability of their arrangement and the great number of their connection points make it conceivable to investigate many stages, including various levels of “loner” or strain between various TMDCs.

The group found that the limit between a monolayer of tungsten diselenide and tungsten disulfide created a “gave” type of light known as circularly energized light, an immediate result of the crease. This new level of control at the nanoscale opens up a universe of opportunities for how their new designs might be applied to genuine gadgets, especially in the field of quantum optoelectronics.

More information: Naoki Wada et al, Efficient and Chiral Electroluminescence from In‐Plane Heterostructure of Transition Metal Dichalcogenide Monolayers, Advanced Functional Materials (2022). DOI: 10.1002/adfm.202203602

Journal information: Advanced Functional Materials