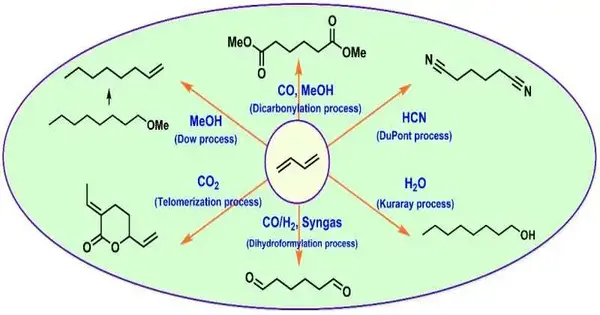

The utilization of 1,3-butadiene as a modest and bountiful natural substance for new applications has drawn more interest in recent years, explicitly in the synthetic business. A recent review examines a number of significant homogeneously catalyzed processes and technologies that are currently utilized to produce fine and bulk chemicals from 1,3-butadiene or have the potential to do so. The application of homogeneous catalysts is the primary focus of this article, which provides readers with concrete examples.

Through the participation of various nucleophiles, palladium-catalyzed telomerization of 1,3-butadiene provides, for instance, versatile platform chemicals for the production of 1-octene, 1-octanol, and higher-value EVP lactones. In the meantime, the synthesis of a variety of polymer precursors, including adiponitrile, adipaldehyde, and adipic diesters, is made simple by effective di-functionalizations of 1,3-butadiene.

The improvement of effective synergistic frameworks plays a key role in empowering molecule financial and specific cycles. The review demonstrates that numerous potential uses for 1,3-butadiene have not yet been investigated in the chemical industry. In general, researchers and professionals in the field can benefit from this review’s useful information on homogeneous catalyst-based industrially relevant transformations of 1,3-butadiene.

“The goal of this review was to provide a comprehensive overview of the current state of the art in the use of 1,3-butadiene as a raw material for chemical production. This molecule is plentiful and very inexpensive, making it an appealing alternative for fine and bulk chemical production. However, there are still other obstacles connected with employing 1,3-butadiene as a feedstock, such as its high reactivity and the possibility of undesired side reactions.”

Author Professor Matthias Beller, Leibniz Institute for Catalysis e.V. (LIKAT).

Beller et al.’s review was published in Industrial Chemistry & Materials.

“The inspiration driving this survey was to give a complete outline of the present status of the craft in involving 1,3-butadiene as a natural substance for compound creation. For the production of bulk and fine chemicals, this compound is an appealing option due to its abundance and low price. “However, there are still many challenges associated with using 1,3-butadiene as a feedstock, including its high reactivity and the possibility of undesirable side effects,” said Professor Matthias Beller, corresponding author, Leibniz Institute for Catalysis (LIKAT) V.

“Several important homogeneously catalyzed processes that are currently utilized or have the potential to produce useful chemicals from 1,3-butadiene are covered in this review. Palladium-catalyzed telomerization, di-functionalization, and other reactions that can result in the production of a variety of chemicals and polymer precursors are examples of these.

“We emphasize the significance of creating effective catalytic systems that can make it possible for selective and atom-economic processes.” We give instances of how various impetuses can be utilized to accomplish explicit substance changes with significant returns and selectivity. The audit additionally features a few likely applications for 1,3-butadiene that are not as of now being investigated in the compound business.”

“When 1,3-butadiene is used as a feedstock, efficient catalytic systems are essential for making selective and long-lasting processes possible. For many chemical transformations involving this compound, advancements in catalyst design have resulted in significant enhancements in selectivity and yield.”

Professor Matthias Beller stated, “I firmly believe that there is still a great deal of potential for exploring new applications of 1,3-butadiene within the chemical industry,” when discussing the future of using 1,3-butadiene as a raw material for chemical production.

“For instance, it could be a useful feedstock for the production of renewable chemicals or a starting material for the synthesis of novel materials with distinct properties. In any case, it will be significant to keep progressing productive synergist frameworks and manageable cycles to conquer the impediments connected with involving this compound as a feedstock.”

More information: Ji Yang et al, Industrially applied and relevant transformations of 1,3-butadiene using homogeneous catalysts, Industrial Chemistry & Materials (2023). DOI: 10.1039/D3IM00009E