Composite particles with submicron sizes can be delivered by illuminating a suspension of nanoparticles with a laser shaft. Brutal physical and substance processes occur during light, a considerable lot of which have been ineffectively perceived to date. As of late, finished tests, conducted at the Institute of Nuclear Physics of the Polish Academy of Sciences in Cracow, have revealed new insight into a portion of these riddles.

At the point when a laser bar strikes agglomerates of nanoparticles suspended in a colloid, occasions happen that are as emotional as they seem to be valuable. The huge expansion in temperature prompts the softening together of nanoparticles into composite molecules. A slender layer of fluid close to the warmed material quickly changes into fume, and entire successions of substance responses happen under states of being that adjust for parts of a second. Utilizing this technique, called laser dissolving, researchers from the Institute of Nuclear Physics of the Polish Academy of Sciences (IFJ PAN) in Cracow delivered new nanocomposites and, in addition, depicted a portion of the inadequately grasped processes liable for their development.

“The laser liquefying process itself, comprising of illuminating particles of material in suspension with unfocused laser light, has been known for a really long time. It is chiefly utilized for the creation of single-part materials. We, as one of just two exploration groups on the planet, are attempting to utilize this strategy to create composite submicron particles. “Around here, the field is still in its infancy, there are still numerous questions, thus our euphoria that a few riddles that baffled us have recently been unwound,” says Dr. aneta witkowska-Warkocka, a teacher at IFJ PAN and co-author of a logical article that was recently distributed in the journal Scientific Reports.

“We are one of only two research teams in the world trying to use the laser melting process to produce composite submicron particles. The field is still in its infancy, there are still many unknowns, thus our joy that several puzzles that perplexed us have been solved.”

Dr. Żaneta Świątkowska-Warkocka, a professor at IFJ PAN

The most generally involved and simultaneously most popular method for the amalgamation of nanomaterials utilizing laser light is laser removal. With this strategy, a naturally visible objective is submerged in a fluid and, afterward, beaten with an engaged laser bar. Affected by photon influences, nanoparticles of material are torn from the objective and end up in the fluid, from which they can later be isolated without any problem.

On account of laser dissolving, the beginning material is nanoparticles recently disseminated in the whole volume of a fluid, where their free agglomerates are shaped. The laser bar utilized for light this time is dissipated, however, so as to give energy in sums adequate to liquefy the nanoparticles. Through laser liquefying, it is feasible to deliver materials built of particles going in size from nanometers to microns, of different compound designs (unadulterated metals, their oxides and carbides) and actual designs (homogeneous, amalgams, composites), including those hard to create with different strategies (for example, gold-iron, gold-cobalt, gold-nickel compounds).

The kind of material shaped during laser dissolving relies upon numerous boundaries. Clearly, the size and substance structure of the beginning nanoparticles are significant, just like the force, productivity, and span of the laser light heartbeats. Current hypothetical models permit researchers from the IFJ PAN to at first arrange the most common way of delivering new nanocomposites, yet practically speaking, the endeavors didn’t necessarily lead to the production of the materials that were normal. Clearly, there were factors included that had not been considered in the models.

This apparatus for the development of nanocomposites by laser liquefying is utilized in research led by the Institute of Nuclear Physics of the Polish Academy of Sciences in Cracow. Photographer: IFJ PAN

Dr. Mohammad Sadegh Shakeri, a physicist at the IFJ PAN answerable for the hypothetical depiction of the cooperation of nanoparticles with laser light, presents one of the issues as follows:

“The agglomerates of approximately associated nanoparticles suspended in the fluid assimilate the energy of the laser pillar, heat up over the softening point, and secure forever while going through more noteworthy or less synthetic changes. Our hypothetical models show that the temperature of nanoparticles can build up to 4,000 kelvin now and again. Sadly, there are no techniques that can straightforwardly quantify the temperature of the particles. However, the temperature and its progressions are the most basic elements influencing the physical and compound construction of the changed material. “

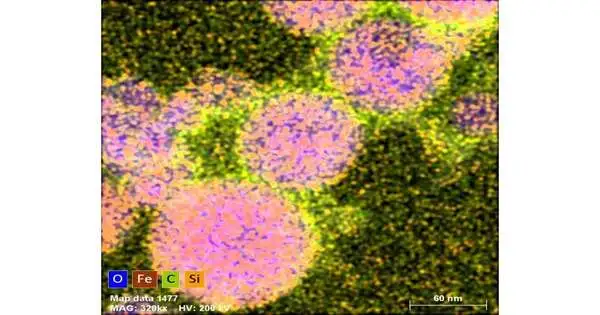

To all the more likely comprehend the idea of the peculiarities happening during laser liquefying, in their most recent exploration, physicists from IFJ PAN utilized alpha-Fe2O3 hematite nanoparticles. They were extracted using three different natural solvents: ethyl liquor, ethyl acetic acid derivation, and toluene.The holder with the pre-arranged colloid was set in an ultrasonic washer, which ensured that there would be no uncontrolled compaction of particles. The examples were then lighted with laser heartbeats lasting 10 ns, rehashed at a recurrence of 10 Hz, which, contingent upon the variant of the trial, brought about the development of particles with sizes ranging from 400 to 600 nanometers.

Point-by-point examinations of the created nanocomposites permitted specialists from the IFJ PAN to find how, contingent upon the boundaries of the shaft utilized, it is feasible to decide the basic size of the particles that initially start to change affected by laser light. It was also confirmed that larger nanocomposite particles arrive at a lower temperature, with hematite particles of sizes close to 200 nm reaching the highest temperature (hypothetical evaluations proposed a value of 2320 K).In any case, the most fascinating outcomes with regard to the analyses ended up being those disturbing fluids.

Most importantly, noticing a connection between the dielectric steady of the fluid and the size of the delivered composite particles was conceivable; the more modest the consistency, the bigger the agglomerates were conceivable. The examinations likewise affirmed the suspicion that a slender layer of fluid close to a warmed nanoparticle goes through quick decay during numerous compound responses. Since these responses occur in various fluids in an unexpected way, the subsequent materials are likewise contrasted in construction and synthetic creation. The particles delivered in ethyl acetic acid derivation were mostly uniform magnetite, whereas ethyl liquor contained a magnetite-wustite composite.

“The role of fluids in the creation of nanocomposites by laser softening ends up being surprisingly significant. We actually have close to zero insight into numerous things. Luckily, our momentum results propose what the following exploration headings ought to be. “A definitive objective is to acquire full information about the cycles occurring in the colloid and construct hypothetical models that would consider the exact nature of both nanocomposite properties and strategies for their creation in a bigger scope,” says Dr. witkowska-Warkocka.

More information: M. S. Shakeri et al, Solvent-particles interactions during composite particles formation by pulsed laser melting of α-Fe2O3, Scientific Reports (2022). DOI: 10.1038/s41598-022-15729-y

Journal information: Scientific Reports