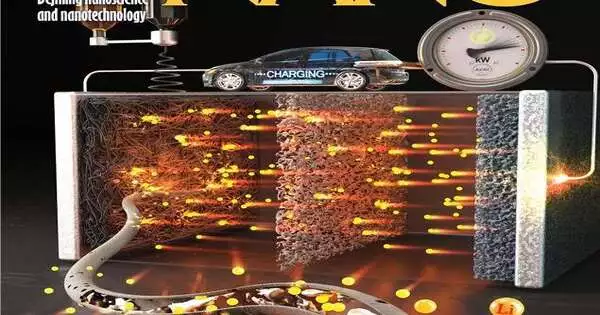

An investigation of Li-metal batteries by the exploration group led by Dr. Byung Gon Kim at the Next-Generation Battery Research Center of Korea Electrotechnology Research Institute (KERI) was distributed as a cover paper in the global journal ACS Nano.

While the ongoing Li-particle batteries create energy by removing Li-particles in and from the graphite anode in view of the intercalation system, the Li-metal battery doesn’t depend on this massive and weighty graphite yet involves metallic Li itself as the anode. Because Li-metal has a higher theoretical limit (3,860 mAh/g) than graphite (372 mAh/g), it has consistently gotten a lot of attention from areas that require high-limit batteries, for example, electric vehicles and energy storage frameworks.

In spite of this benefit, Li can fill up looking like a tree limb, called a Li dendrite, in the event that it isn’t consistently and really put away while the cycling process, prompting huge volume extension of the cathode, which thus might abbreviate the battery’s cycle life and cause security issues, for example, fire and blast set off by inner shortcircuits.

To handle this issue, KERI created a 1D Li-confinable permeable carbon structure with an empty center, and a few gold nanoparticles with Li fondness were deeply added. Here, the gold controls the development course of Li by specially responding to Li, inciting Li’s testimony inside the center. Also, numerous nano-sized pores are framed in the shell part to further develop the Li-particle development toward the center space.

“Despite its great capacity, Li-metal batteries have several challenges in commercialization, mostly owing to stability and safety concerns. Our research is important because we established a method for mass producing Li-metal reservoirs with excellent coulombic efficiency for fast-rechargeable Li-metal batteries.”

Dr. Byung Gon Kim at Next-Generation Battery Research Center of Korea Electrotechnology Research Institute (KERI)

A significant test found in the current empty center shell Li host was the Li statement on the conductive carbon shell, not inside the center, under high-rate charging conditions. Hence, the KERI group acquainted numerous nano-sized pores with the shell, and accomplished essentially improved coulombic proficiency without much Li dendrite development under a high-current testing state of 5 mA/cm2.

Dr. Kim’s group teamed up with Prof. Janghyuk Moon at Chung-Ang University for hypothetical approval of the adequacy of this material’s plan, and the recreation results showed that the decreased Li particle dispersion length by the shell pores and the worked on Li fondness by the gold nanoparticles kept Li affidavit inside the design much under high-current charging conditions. Besides, the planned Li host showed great cycling execution of north of 500 cycles under a high current thickness of 4C rate (82.5% limit maintenance). It is also obvious that this innovation meets common sense because the group included the electrospinning method with advantages in large scale manufacturing for material blends.

“In spite of the value of the high limit, the Li-metal batteries have many obstacles to be defeated for commercialization, mostly because of security and well-being issues,” said Dr. Kim. Also, Dr. Kim likewise said, “Our review is priceless in that we fostered a method for large-scale manufacturing of Li-metal supplies with high coulombic proficiency for quick battery-powered Li-metal batteries.”

This concentrate by the KERI research group was distributed as a valuable cover paper in the August version of ACS Nano.

More information: Dong Woo Kang et al, One-Dimensional Porous Li-Confinable Hosts for High-Rate and Stable Li-Metal Batteries, ACS Nano (2022). DOI: 10.1021/acsnano.2c01309

Journal information: ACS Nano