Magnesium diboride (MgB2) is a non-toxic, low-cost superconductor that is utilized in generators, electric motors, and field magnets. However, it costs a lot to make nanoscale boron (B) particles for MgB2. Using high-energy ultrasonication in 2-propanol, a solvent with a high viscosity, researchers recently solved this problem by producing B particles of the nm size without any impurities. The method is economical and makes it possible to produce bulk MgB2 with a high critical current density, which is necessary for the long-term production of high-performance superconducting magnets.

At a moderate temperature of around 39 K (-234°C), the binary compound magnesium diboride (MgB2) behaves as a superconductor—a substance that does not resist the flow of electric current through it. Liquid hydrogen or neon coolants, which are relatively inexpensive, can be used to reach this temperature.

Additionally, MgB2’s precursors, magnesium (Mg) and boron (B), are readily available, making it an inexpensive, lightweight, and non-toxic material. As a consequence of this, it is capable of replacing magnets based on neodymium, a rare element, as well as iron and boron, as well as conventional low-temperature superconductors that necessitate costly liquid helium for cooling.

“Ultrasonic vibrations impart high speeds to B particles in the solvent in this technique, resulting in collisions.” The friction and shear tearing, compression, and energy release caused by the collapsing of microscopic air bubbles created after contact break down B particles to nanoscale levels.”

Prof. Muralidhar Miryala from Shibaura Institute of Technology (SIT),

MgB2 tracks down a great many applications, including the production of loops and magnets for attractive reverberation imaging, atomic attractive reverberation, attractive medication conveyance, shortcoming flow limiters, electric engines, and transportation. MgB2 is a good candidate for polycrystalline superconducting magnets because it has a high trapped magnetic field (TF) and a high critical current density (Jc), according to research.

However, it has limited pinning by magnetic flux. Tuning the pinning centers of MgB2, which are the boundaries of the grains or small crystals that make up MgB2, is essential in order to improve pinning. To this end, analysts have now shown how nano-sized B particles can be utilized as B antecedents to manufacture nano-sized MgB2 grains with serious areas of strength for limit sticking and high Jc.

Ball milling, pyrolysis, and sintering are currently used to make B nanoparticles. However, these methods have drawbacks like low purity output and poor cost-effectiveness, requiring better alternatives. To this end, a group of researchers led by Prof. Muralidhar Miryala from Shibaura Institute of Technology (SIT) in Japan recently looked into high-energy ultrasonication as a less expensive option for reducing 2-propanol-dispersed coarse B powder to nanoscale sizes. The Journal of Alloys and Compounds published their findings.

“In this method, B particles in the solvent are accelerated by ultrasonic vibrations, resulting in collisions.” Prof. Miryala elaborates, “B particles are broken down to nanometer sizes by the resulting friction and shear tearing, compression, and energy release by the collapse of tiny air bubbles produced during collision.”

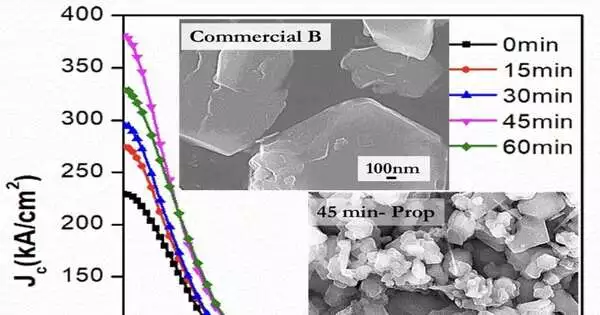

The researchers produced oxide-free, nm-sized B particles by ultrasonically refining inexpensive commercial B powder for 45 minutes with 2-propanol as the solvent. They then used them to make bulk MgB2 that was superconducting at around 38.5 K and had no carbon impurities or oxide. It also had high Jc values of 500 kA cm2 at 10 K and 380 kA cm2 at 20 K, respectively. The last option of these Jcvalues denoted an 80% improvement compared with that for mass MgB2 arranged from modest B powder and was at standard with that for costly business B powder. The expansion in Jc was due to better grain limit sticking in MgB2, as uncovered by microstructural examination and hypothetically upheld by the Dew-Hughes hypothesis.

Finally, the researchers used field cooling magnetization simulations to predict that an ultrasonically refined B powder-prepared 40-mm-wide and 10-mm-thick MgB2 disk could have a high TF of 2.5 teslas. Prof. Miryala says that these findings bring MgB2 superconducting magnets, which can be made into films, tapes, and wires, one step closer to being sold.

More information: A. Sai Srikanth et al, Tuning of grain boundaries in MgB2 by boron ultra-sonication in 2-propanol—A way to low-cost high-J bulk superconducting magnets, Journal of Alloys and Compounds (2023). DOI: 10.1016/j.jallcom.2023.170146