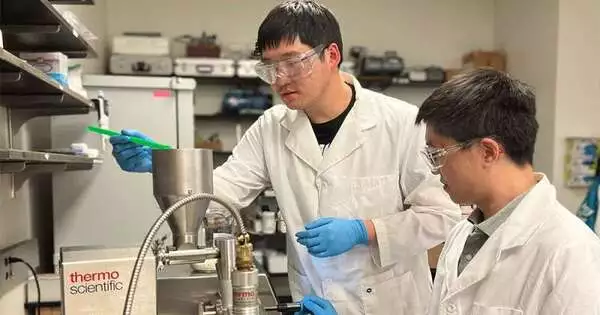

Dr. Qingsheng Wang, academic partner and George Armistead ’23 Faculty Fellow in the Artie McFerrin Department of Chemical Engineering at Texas A&M University, and his group of analysts have gone through nearly three years tracking down additional effective methods for assembling metal-natural system (MOF)-based composites for modern applications like fire retardants.

MOFs are a class of glasslike materials with long-lasting porosity and wide applications, including gas purging, gas division, water remediation, catalysis, and medication conveyance. Nonetheless, as the utilization and applications of MOF-based composites grow, process improvement is expected to produce MOFs at a higher level in the industry.

“To create MOFs requires a profound understanding of cycle designing and rigid circumstances, and even with that, only a modest quantity can be delivered at a time.” Numerous changes are expected to work on the cycle to efficiently manufacture MOFs. “

“By using reactive extrusion manufacturing, we can take the starting material mixed with a polymer to generate MOFs and immediately mix it with plastics, bypassing many reaction stages in typical hydrothermal procedures.”

Dr. Qingsheng Wang, associate professor

Wang’s group has distributed four examinations in ACS Publications in regards to their revelations on MOF strength, MOF improvement processes, producing MOF-based composites, and their applications in fire retardancy.

Most MOF-polymer composites are currently prepared using a discretely based up rule that necessitates complex compound responses mixed inside various polymers in various arrangements.This multi-step process involves a huge amount of time, energy, and cash to create negligible amounts.

By joining portions of the MOF’s improvement cycle, Wang’s group has found a one-step strategy utilizing response expulsion to create MOF-put together composites with respect to a bigger scope securely and really. Along with the warming condition, applied shear and compressive powers, MOFs can meet the expected response conditions for mechanochemical union.

Also, the discoveries give new experience in making MOF-based polymer frameworks for polyolefins, reducing their smoke outflows and upgrading fire retardancy during burning. The strategy also improved security and proficiency by improving the MOF’s thermal strength and mechanical properties while decreasing its combustibility.

This work was recently published in ACS Sustainable Chemistry and Engineering.

“In the event that we utilize receptive expulsion fabricating, we can take the beginning material joined with a polymer to create MOFs and straightforwardly blend it in with plastics by ignoring a few response steps in regular aqueous techniques,” said Wang. “Utilizing this cycle, every day we can get around the kilogram scale, contrasting with the customary strategy, which normally can only create the gram scale.”

They desire to see this strategy utilized in the industry for advancing manageability endeavors, process improvement, and cycle security.

In their review published in Industrial and Engineering Chemistry Research, Wang showed the utilization of MOF as a fire resistant material. A monetarily accessible MOF was integrated into an intumescent fire resistant/polypropylene (IFR/PP) composite framework. The outcomes show that the added substances display areas of strength for an impact between them for the development of the development and security of the intumescent singe layer to forestall the serious consumption of PP.

These discoveries could further develop IFR frameworks for polyolefins, reducing their smoke outflows during burning. Taking into account that every one of the natural substances is monetarily accessible and the planning strategy is viable with current modern cycles, the system introduced in this study can be extended for modern applications.

“We can utilize MOFs in so many countless ways—from water treatment to carbon capture,” Wang said. “I might want to keep further developing this cycle so industry can involve MOFs for a bigger scope in different helpful applications.”

More information: Yufeng Quan et al, Sustainable and Efficient Manufacturing of Metal-Organic Framework-Based Polymer Nanocomposites by Reactive Extrusion, ACS Sustainable Chemistry & Engineering (2022). DOI: 10.1021/acssuschemeng.2c01720

Ruiqing Shen et al, Metal–Organic Framework as an Efficient Synergist for Intumescent Flame Retardants against Highly Flammable Polypropylene, Industrial & Engineering Chemistry Research (2022). DOI: 10.1021/acs.iecr.2c00715