Aspherical parts in optical frameworks can build the free plan factors without presenting new deviations. That brings further developed imaging quality and decreased size and weight. Aspheric parts are generally utilized in top-of-the-line optoelectronic instruments, for example, space and ground-based galactic telescopes, profound space investigation stages, and earth perception optics.

The two basic determinations of a telescope framework are the precise goal (AR) and light gathering limit (LCC). These determinations are firmly connected with the gap in the framework. AR is contrarily relative to the telescope’s measurement, while LCC corresponds to its squared worth. The bigger the gap, the higher the AR and the more grounded the LCC. Subsequently, expanding the opening becomes crucial for working on the telescope’s presentation. For that reason, both cosmology and earth-noticing networks need huge telescopes.

The larger size of the primary mirror in today’s ground-based telescopes and space cameras puts pressure on reflect materials and full-spatial recurrence (FSF) shape blunders control.Forward leaps in reflective materials that help precise and effective assembling of enormous aspherical mirrors are critically anticipated.

In another paper distributed in Light: Science and Applications, a group of researchers led by Teacher Xuejun Zhang from the Changchun Establishment of Optics, Fine Mechanics, and Physical Science have fostered a few new strategies for assembling huge mirrors. Their paper, titled “Difficulties and procedures in high-exactness assembling of the world’s biggest SiC aspheric mirror,” saw the group construct its biggest aspheric mirror.

Credit: Light: Science and Applications (2022). DOI: 10.1038/s41377-022-00994-3

SiC has higher explicit firmness (SS) and layered dependability (DS). It is appropriate for cruel climate applications. The response fortified silicon carbide (RB-SiC) cycle can create a semi-shut back structure, further expanding its SS and DS. The enormous gap SiC reflects is quickly becoming another number one in the world’s telescope local area.Producing huge SiC reflects with a width of multiple m is very difficult. There are also intricate actual stage changes and synthetic responses.

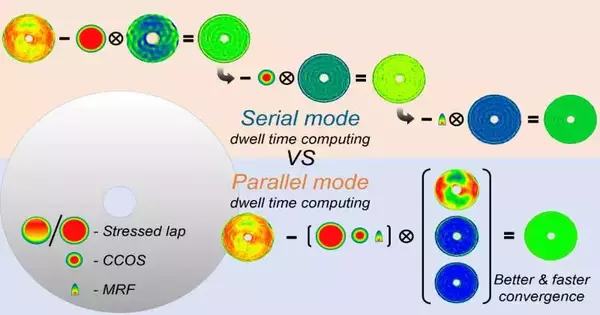

Existing innovation isn’t versatile enough to mirror over 1.5 m in breadth. The trouble of assembling aspheric mirrors is proportional to the third force of the gap. The biggest magnetorheological get done (MRF) cleaning gear has a maximum handling size of 2.5 m.

Credit: Light: Science and Applications (2022). DOI: 10.1038/s41377-022-00994-3

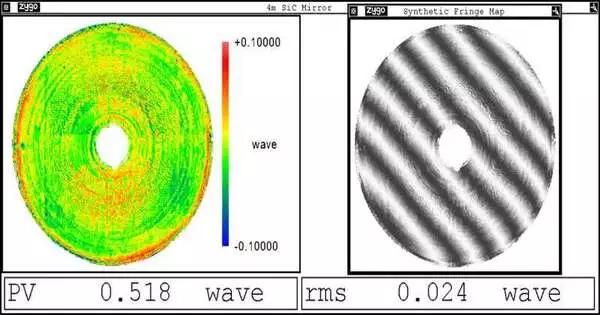

The specialists have fabricated a 3 m wide solid SiC reflector. They similarly caused a 4.03 m width To put it another way, clear by response shaped joint innovation.Utilizing a home-fabricated MRF24 cleaning machine with a greatest handling scope of 4.5 m breadth, a 4.03 m SiC aspheric mirror was cleaned to high exactness.

The scientists likewise proposed a PVD cladding interaction to further develop the substrate surface quality. A dainty cladding layer of Si was saved on the substrate surface, with its deformities covered with silicon material. The low handling temperature saw an exceptionally low deformity rate.

More information: Xuejun Zhang et al, Challenges and strategies in high-accuracy manufacturing of the world’s largest SiC aspheric mirror, Light: Science & Applications (2022). DOI: 10.1038/s41377-022-00994-3

Journal information: Light: Science & Applications