The connection between microstructure development and property corruption of two delegate second-stage scattering fortified tungsten materials after electron bar warm stacking has been explored as of late by a working group from Hefei Foundations of Actual Science (HFIPS) and the Chinese Institute of Sciences (CAS).

The connected examination was distributed in the Diary of Materials Science and Innovation.

The best climate for human endurance is 25 °C. In any case, the plasma-confronting tungsten (W) materials in the attractive control atomic combination gadgets are straightforwardly presented to high-temperature plasma and are commonly exposed to steady-state warm heaps of 5–20 MW/m2 and transient warm shocks of 1 GW/m2, which can raise the surface temperature of tungsten to over 1800 °C. The high intensity motion burden in W causes some irreversible material damages, such as surface roughening, breaking, and surface softening.Hence, assessing the thermal resistance of W materials is dire.

“Because the Y2O3 phase and W have different coefficients of thermal expansion (CTEs), irreversible plastic deformation of the W matrix occurs, particularly around the coarse Y2O3 particles, resulting in interface debonding between Y2O3 particles and the W matrix.”

Wu Xuebang,

In this review, scientists did low-intensity loads on an electron bar gadget (30 kW: Electron-bar Material-Research Stage, or EBMP-30). This stage was created specifically to evaluate the warm shock resistance of plasma-confronting materials (PFMs).

“It takes on a 30 kW welding electron bar with a maximum speed increase voltage of 100 kV,” explained XIE Zhuoming, who assisted in the stage’s construction, “it can check a 30 30 mm2 region with a maximum edge pace of 35 kHz, and its heartbeat span can change from 100 ms to a nonstop state.”

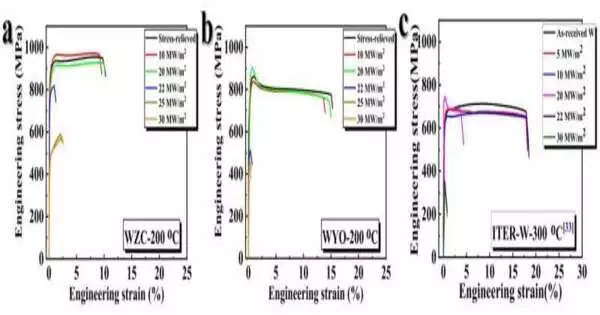

Based on the EBMP-30 device, two agent W-0.5 wt% ZrC (WZC) and W-1.0 wt% Y2O3 (WYO) composites were chosen to focus on the harm conduct caused by rehashed consistent state heat loads with consumed power thickness (APD) ranging from 10 to 30 MW/m2.

The results show that when APD 20 MW/m2, the microstructures and elastic properties of the WZC and WYO examples do not change significantly.Nonetheless, at APD 22 MW/m2, full recrystallization and grain development in WYO examples were observed, as well as Y2O3 particles shedding from the W grid.

Also, the definitive rigidity and all-out extension of WYO diminished from 861 MPa to 510 MPa and from 15% to approach zero, separately.

“Because of the various coefficients of warm extension (CTEs) of the Y2O3 stage and W, irreversible plastic twisting of the W grid happens, particularly around the coarse Y2O3 particles,” said Wu Xuebang, who drove the group, “which prompts the connection point debonding between Y2O3 particles and the W lattice.”

After warm loads at 22 MW/m2, WZC examples kept up with the high extreme rigidity of 816 MPa because of its high recrystallization temperature (1300 °C).

“The fine and uniform dispersion of ZrC particles and its similar CTE to the W grid,” Wu added, “really dodges ZrC molecule shedding and the development of microcracks.”

“This study reveals the links between microstructure advancement and execution corruption in two agent second-stage scattering reinforced tungsten materials, as well as the system of weakness harm caused by high warm loads,” WU said, “which gives a significant reference to the further advancement of elite execution tungsten materials.”

More information: Hui Wang et al, Microstructural evolution and thermal fatigue damage mechanism of second-phase dispersion strengthened tungsten composites under repetitive thermal loads, Journal of Materials Science & Technology (2022). DOI: 10.1016/j.jmst.2022.09.007