Toward the end of 2022, specialists at Lawrence Livermore National Laboratory reported they had noticed a net energy gain through atomic combination for the absolute first time. This stupendous achievement toward combination energy addresses a colossal leap forward in fueling our homes and organizations with a carbon-impartial energy source. However, changing this logical accomplishment into a useful power source likewise requires new innovations to make a combination-fueled society a reality.

Researchers at Pacific Northwest National Laboratory (PNNL) and Virginia Polytechnic Foundation and State College (Virginia Tech) are carrying this objective to completion through their materials research endeavors. Their new work, distributed in Logical Reports, presents the defense for tungsten-weighty amalgams and demonstrates the way that they can be improved for use in cutting-edge atomic combination reactors by emulating the design of shells.

“This is the main review to notice these material connection points at such small length scales,” said Jacob Haag, the first creator of the exploration paper. “In doing so, we uncovered a portion of the key components that oversee material strength and sturdiness.”

“This is the first study to look at material interactions on such short length scales. As a result, we discovered some of the underlying mechanisms that determine material toughness and durability.”

Jacob Haag, first author of the research paper.

Enduring the intensity

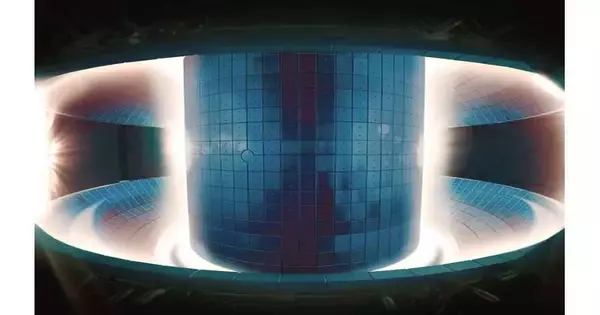

The sun, with a center temperature of around 27 million degrees Fahrenheit, is fueled by atomic fusion. Hence, it ought to shock no one that combinations of responses produce a great deal of intensity. Before researchers can harness combination energy as a power source, they need to make advanced atomic combination reactors that can endure the high temperatures and light circumstances that accompany combination responses.

Of the multitude of components on the planet, tungsten has quite possibly the greatest dissolving point. This makes it an especially alluring material for use in combination reactors. Nonetheless, it can also be extremely weak. Blending tungsten with limited quantities of different metals, like nickel and iron, makes a combination that is harder than tungsten alone while still holding its high dissolution temperature.

It isn’t simply their piece that gives these tungsten-weighty amalgams their properties; thermomechanical treatment of the material can adjust properties like elasticity and break durability. A specific hot-moving method produces microstructures in tungsten-weighty compounds that copy the design of nacre, otherwise called mother-of-pearl, in shells. Nacre is known to display uncommon strength, notwithstanding its wonderful, brilliant varieties. The PNNL and Virginia Tech research groups explored these nacre-impersonating tungsten-weighty composites for potential atomic combination applications.

“We needed to comprehend the reason why these materials display almost exceptional mechanical properties in the field of metals and combinations,” said Haag.

Looking at microstructures for significant strength

Haag and his colleagues used advanced materials portrayal procedures, such as filtering transmission electron microscopy, to examine the microstructure of the compounds. They also used a combination of energy dispersive X-beam spectroscopy and molecular tomography to plan the nanoscale organization of the material point of interaction.

The tungsten-heavy compound is divided into two stages within the nacre-like structure: a “hard” period of nearly pure tungsten and a “flexible” stage containing a combination of nickel, iron, and tungsten.The exploration discoveries recommend that the high strength of tungsten-weighty composites comes from a phenomenal connection between the different stages, including personally reinforced “hard” and “malleable” stages.

“While the two particular stages make an extreme composite, they present critical difficulties in planning top-notch examples for portrayal,” said Wahyu Setyawan, PNNL computational researcher and co-creator of the paper. “By doing so, our colleagues were able to uncover the detailed construction of interphase limits as well as the science degree across these limits.”

The review shows how precious stone construction, calculation, and science add major areas of strength to interfaces in tungsten-weighty compounds. It also reveals methods for working on material plans and properties for combination applications.

“If these bi-stage combinations are to be used inside an atomic reactor, it is critical to streamline them for wellbeing and life span,” Haag said.

Building the up-and-coming age of combination materials

The findings presented in this study are currently being developed in many areas within PNNL and in the logical examination area. Multiscale material displaying research is in progress at PNNL to upgrade the design, science, and strength of divergent material connection points, as well as conduct exploratory examinations to see how these materials act under the outrageous temperatures and light states of a combination reactor.

“It is an amazing time for the combination of energy with reestablished interests from the White House and the confidential areas.”The exploration that we do in finding material answers for delayed activities is fundamentally expected to speed up the acknowledgment of combination reactors,” said Setyawan.

Extra PNNL creators are Jing Wang (previously of PNNL), Karen Kruska, Matthew Olszta, Charles Henager, Danny Edwards, and Mitsu Murayama, who likewise holds a joint meeting with Virginia Tech.

More information: J. V. Haag et al, Investigation of interfacial strength in nacre-mimicking tungsten heavy alloys for nuclear fusion applications, Scientific Reports (2023). DOI: 10.1038/s41598-022-26574-4

Journal information: Scientific Reports