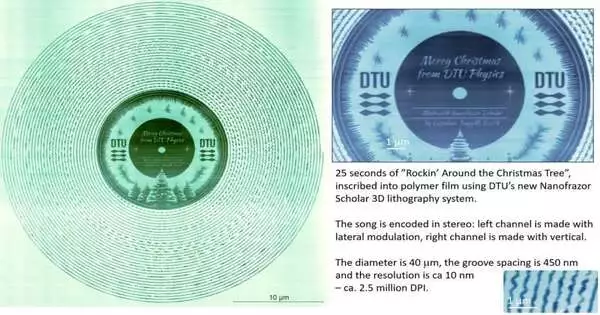

DTU Material Science specialists have made the smallest record at any point cut, measuring just 40 micrometers in width.Including the initial 25 seconds of the exemplary “Shaking Around the Christmas Tree,” the single is cut utilizing a new nano-chiseling machine, the Nanofrazor, as of late procured from Heidelberg Instruments.

The Nanofrazor can etch 3D examples into surfaces with nanoscale precision, permitting the analysts to make new nanostructures that might prepare for novel advances in fields like quantum gadgets, attractive sensors, and electron optics.

“I have done lithography for quite a long time, and in spite of the fact that we’ve had this machine for some time, it actually feels like sci-fi.” We’ve done many examinations, such as making a duplicate of the Mona Lisa in a 12 by 16-micrometer region with a pixel size of ten nanometers. We also printed an 8 by 12-micrometer image of DTU’s founder, Hans Christian rsted, with a pixel size of 2,540,000 DPI.”To find out about the scale we are working at, we could compose our marks on a red platelet with this thing,” says Teacher Peter Bggild from DTU Physical Science.

“Quantum soap bubbles are smooth electrical potentials with intentionally designed defects. We can control how electrons flow in graphene by doing so. We seek to understand how electrons move in manufactured disordered potentials and see if this could become a new platform for sophisticated neural networks and quantum information processing.”

Nolan Lassaline

“The most extreme thing is that at that insane goal, we can make freestyle 3D scenes—this dim-scale nanolithography is a genuine major advantage for our exploration.”

Nanoscale Christmas record, in surround sound

The Nanofrazor isn’t similar to a printer adding material to a medium; all things considered, it works like a CNC (computer numerical control) machine eliminating material at exact areas, abandoning the ideal shape. Due to the smaller-than-expected images of the Mona Lisa and H.C. Ørsted, the final image is distinguished by the line-by-line evacuation of polymer until an ideal dark-scale image emerges. To Peter Bøggild, a beginner performer and vinyl record fan, cutting a nanoscale record was self-evident.

“We concluded that we should attempt to print a record.” We’ve taken a scrap of “Shaking Around The Christmas Tree” and have cut it very much like you would cut an ordinary record—despite the fact that, since we’re dealing with the nanoscale, this one isn’t playable on your normal turntable. The Nanofrazor was given something to do as a record-cutting machine—changing over a sound signal into a spiraled groove on the outer layer of the medium. For this situation, the medium is an unexpected polymer in comparison to vinyl.

“We even encoded the music in surround sound—tthe horizontal wriggles are the left channel, while the profundity adjustment contains the right channel.” It could be excessively illogical and costly to turn into a hit record. “To peruse the notch, you want a fairly exorbitant nuclear power magnifying instrument or the Nanofrazor, yet it is certainly feasible.”

Credit: DTU Physics.

Rapid, low-cost nanostructures

The NOVO Establishment Award for BIOMAG, which made the Nanofrazor dream conceivable, isn’t tied in with cutting Christmas records or printing pictures of celebrities. Peter Bøggild and his associates, Tim Stall and Nolan Lassaline, have different plans. They expect that the Nanofrazor will permit them to shape 3D nanostructures in very exact detail and do as such for a rapid and minimal price—something unthinkable with existing devices.

“We work with 2D materials, and when these ultrathin materials are painstakingly set down on the 3D scenes, they follow the forms of the surface.” So, they bend, and that is a strong and completely better approach for “programming” materials to do things that nobody would accept were conceivable only a long time ago. For example, when bent in the perfect way, graphene acts as though there is a giant attractive field when, truth be told, there is none. “We can also bend it perfectly with the nanofrazor,” says Peter Bggild.

Academic partner Tim Stall adds, “The way that we can now precisely shape the surfaces with nanoscale accuracy at essentially the speed of the creative mind is a distinct advantage for us.” We have numerous thoughts about what to do right away and accept that this machine will fundamentally accelerate the prototyping of new designs. Our fundamental objective is to foster novel, attractive sensors for distinguishing flows in the living cerebrum inside the BIOMAG project. In any case, we additionally anticipate making exactly etched likely scenes with which we can more readily control electron waves. “There is a lot of work to do.”

Postdoc Nolan Lassaline (who cut the Christmas record) plans to make “quantum cleanser rises” in graphene. He plans to use the Nanofrazor to investigate better methods for organizing nanomaterials and to foster novel methods for controlling electrons in molecularly thin materials.

“Quantum cleanser bubbles are smooth electronic possibilities where we add misleadingly customized messes.” Thusly, we can control how electrons stream in graphene. “We want to comprehend how electrons move in deliberately cluttered possibilities and investigate whether this could turn out to be another stage for cutting edge brain organizations and quantum data handling,” Lassaline says.

The Nanofrazor framework is currently important for the DTU Physical Science NANOMADE’s novel creation office for air-touchy 2D materials and gadgets and some portion of E-MAT, a more prominent biological system for air-delicate nanomaterials handling and manufacture, driven by Prof. Nini Pryds, DTU Energy.

Provided by Technical University of Denmark