Sun powered chargers, otherwise called photovoltaics, depend on semiconductor gadgets, or sun-based cells, to change energy from the sun into power.

To create power, sun-based cells need an electric field to isolate positive charges from negative charges. To get this field, makers normally dope the sun-based cell with synthetics, so one layer of the gadget bears a positive charge and another layer a negative charge. This intricate scheme ensures that electrons flow from a device’s negative to positive sides — an important factor in device security and performance.Yet, compound doping and layered blends likewise add extra expensive strides in solar cell production.

Presently, a group of specialists led by researchers at DOE’s Lawrence Berkeley National Laboratory (Berkeley Lab), as a team with UC Berkeley, has shown a novel workaround that offers an easier way to deal with sun-based cell production: A glasslike solar powered material with an implicit electric field — a property empowered by what researchers call “ferroelectricity.” The material was accounted for recently in the diary Science Advances.

The new ferroelectric material — which is made in the lab from cesium germanium tribromide (CsGeBr3 or CGB) — makes way for a simpler way to deal with making solar-based cell gadgets. CGB gems are innately energized where one side of the gem develops positive charges and the opposite side develops negative charges, with no doping required.

“Imagine a lead-free solar material that not only collects energy from the sun but also has the extra benefit of having a naturally, spontaneously produced electric field—the potential in the solar energy and electronics sectors are fairly fascinating.”

Co-senior author Peidong Yang,

In addition to being ferroelectric, CGB is a non-lead “halide perovskite,” a developing class of sun-based materials that have captivated scientists for their moderateness and simplicity of union when compared to silicon.Yet, large numbers of the best-performing halide perovskites normally contain the component lead. As per different analysts distributing in Materials Today Energy in 2017, lead leftovers from perovskite solar-based material creation and removal could taint the climate and present general well-being concerns. Thus, analysts have looked for new halide perovskite plans that shun lead without compromising execution.

“In the event that you can envision a sans lead sun-based material that harvests energy from the sun as well as has the special reward of having a normally, suddenly framed electric field — the potential outcomes across the sun-powered energy and gadget ventures are really energizing,” said co-senior creator Peidong Yang, a main nanomaterials master known for his spearheading work in one-layered semiconducting nanowires for novel sun-oriented cell advances and fake photosynthesis. He is a senior staff researcher in Berkeley Lab’s Materials Sciences Division and a teacher of science and materials science and design at UC Berkeley.

CGB could likewise propel another age of exchanging gadgets, sensors, and super-stable recollections that answer light, said co-senior creator Ramamoorthy Ramesh, who held titles of senior staff researcher in Berkeley Lab’s Materials Sciences Division and teacher of materials science and design at UC Berkeley at the hour of the review and is currently VP of examinations at Rice University.

Perovskite sun-based films are normally made utilizing minimal expense covering strategies, for example, turn covering or ink fly printing. What’s more, unlike normal for silicon, which requires a handling temperature of around 2,732 degrees Fahrenheit to make into a sun-based gadget, perovskites are handily handled from arrangement at room temperature to around 300 degrees Fahrenheit — and for producers, these lower handling temperatures would decisively lower energy costs.

Yet, in spite of their likely lift to the sun-based energy area, perovskite sun-powered materials will not be market-prepared until analysts overcome well-established difficulties in item blend and security, and material manageability.

Nailing down the ideal ferroelectric perovskite

Perovskites solidify from three unique components, and each perovskite gem is outlined by the compound recipe ABX3

Because their glasslike nuclear design is similar to a snowflake, most perovskite sun-based materials are not ferroelectric.In recent years, sustainable power analysts like Ramesh and Yang have been on the hunt for colorful perovskites with ferroelectric potential — explicitly, awry perovskites.

A couple of years prior, first creator Ye Zhang, who was a UC Berkeley graduate understudy scientist in Yang’s lab at that point, considered how she could make a sans lead ferroelectric perovskite. She guessed that setting a germanium iota in the focal point of a perovskite would twist its crystallinity barely enough to cause ferroelectricity. What’s more, a germanium-based perovskite would free the material from lead. (Zhang is presently a postdoctoral scientist at Northwestern University.)

Yet, despite the fact that Zhang had focused on germanium, there were still vulnerabilities. Concocting the best non-lead, ferroelectric perovskite recipe is comparable to locating a difficult to find small item.There are a great many potential plans.

So Yang, Zhang, and group cooperated with Sinéad Griffin, a staff researcher in Berkeley Lab’s Molecular Foundry and Materials Sciences Division who works in the plan of new materials for various applications, including quantum figuring and microelectronics.

With help from the Materials Project, Griffin utilized supercomputers at the National Energy Research Scientific Computing Center (NERSC) to perform hypothetical estimations in view of a strategy known as the thickness useful hypothesis.

For these estimations, which take nuclear design and compound species as info and can foresee properties like electronic construction and ferroelectricity, Griffin and her group focused in on CGB, the main all-inorganic perovskite that marked off every one of the cases on the analysts’ ferroelectric perovskite list of things to get: Is it awry? Indeed, its nuclear design looks like a rhombohedran, the square shape’s screwy cousin. Is it actually a perovskite? Indeed, its compound recipe — CeGeBr3 — matches the perovskite’s obvious design of ABX3.

The scientists guessed that the uneven situation of germanium in the focal point of the gem would make it possible that, similar to an electric field, positive electrons would be isolated from negative electrons to create power. Yet, would they say they were correct?

Estimating CGB’s ferroelectric potential

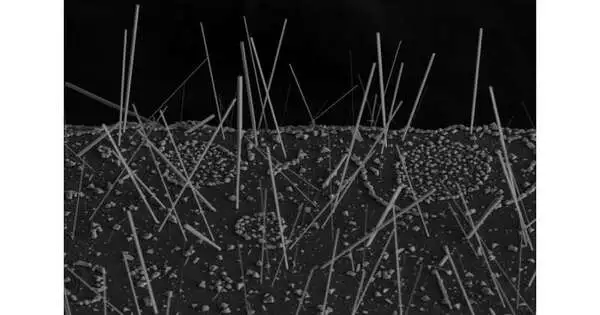

To find out, Zhang made small nanowires (100 to 1,000 nanometers in width) and nanoplates (around 200 to 600 nanometers thick and 10 microns wide) of single-glasslike CGB with uncommon control and accuracy.

“My lab has been attempting to sort out some way to substitute lead with less harmful materials for a long time,” said Yang. “Ye fostered an astounding method to develop single-gem germanium halide perovskites—and it’s a lovely stage for concentrating on ferroelectricity.”

CGB’s uneven glasslike structure, a sign of ferroelectricity, was uncovered by X-beam tests at the Advanced Light Source. Electron microscopy tests driven by Xiaoqing Pan at UC Irvine revealed more proof of CGB’s ferroelectricity: an “uprooted” nuclear design offset by the germanium place.

In the meantime, electrical estimation tests conducted in the Ramesh lab by Zhang and Eric Parsonnet, a UC Berkeley physical science graduate understudy scientist and co-creator of the review, uncovered a switchable extremity in CGB, fulfilling one more necessity for ferroelectricity.

Yet, the last test — photoconductivity estimations in Yang’s UC Berkeley lab — yielded a great outcome and a shock. The scientists observed that CGB’s light retention is tunable—crossing the range of noticeable to bright light (1.6 to 3 electron volts), an ideal reach for cajoling high energy change efficiencies in a sun-based cell, Yang said. Such tunability is seldom found in customary ferroelectrics, he noted.

Yang says there is even more work to be finished before the CGB material can make its presentation in a business-based gadget, yet he’s energized by their outcomes up to this point. “This ferroelectric perovskite material, which is basically a salt, is shockingly flexible,” he said. “We anticipate testing its actual likelihood in a truly photovoltaic gadget.”.

More information: Ye Zhang et al, Ferroelectricity in a semiconducting all-inorganic halide perovskite, Science Advances (2022). DOI: 10.1126/sciadv.abj5881

Longbin Qiu et al, Advances and challenges to the commercialization of organic–inorganic halide perovskite solar cell technology, Materials Today Energy (2017). DOI: 10.1016/j.mtener.2017.09.008

Journal information: Science Advances