Ling Li, partner teacher in Virginia Tech’s Branch of Mechanical Design, has revealed a secret in the permeable microstructures of ocean imp exoskeletons that could prompt the making of lightweight engineered pottery. His discoveries were published in Nature Correspondences.

Pottery is extremely resistant to heat, making it a popular choice for dealing with the extreme heat demands of fast vehicles that travel faster than the speed of sound.At those very fast paces, packed air makes huge contact with the vehicle, bringing about a quick ascent in the intensity it experiences.

Heat resistance might be the strength of pottery, yet damage resilience is a shortcoming. A solitary pinpoint influence in a clay plate can result in a quickly spreading break that causes all-out structural disappointment. In any case, pottery becomes even less lenient to harm when it is made permeable for weight decrease; in any case, diminishing weight is a basic necessity for the majority of primary applications, including fast vehicles.

“We believe we have discovered some of the essential principles that allow the sea urchin to be strong and durable while also offering weight savings due to its porous microstructure. This Nature Communications study describes the findings of what is concealed inside.”

Ling Li, assistant professor in Virginia Tech’s Department of Mechanical Engineering,

The U.S. Flying Corps, one of the backers of Li’s exploration, has for some time been keen on working on the mechanical execution of clay materials. As well as getting monetary help from the Flying Corps Office of Logical Exploration, Li’s group additionally got assets from the Public Science Establishment.

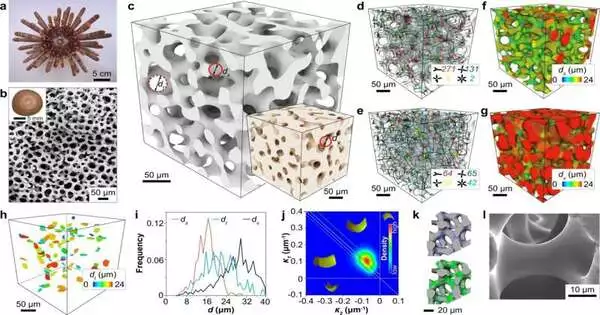

These joined assets, obtained by the lab in 2018, have prepared analysts to investigate new standards implanted in the normal clay cell solids shaped by creatures like ocean imps. An ocean imp’s exoskeleton is one kind of cell froth, or “froth,” presumably on the grounds that its microstructure is a gathering of open cells with strong edges or faces, stuffed together so they occupy space. The holes between the phones make them permeable, creating a material that can be more precisely effective than thick designs.

Instructions to deal with the harm like an ocean imp

“In this work, we assume we discovered a portion of the key systems that enable the ocean imp to be solid and extreme while offering weight decrease with its permeable microstructure,” said Li. “This Nature Interchanges paper reports the outcomes we found of what is concealed inside.”

The spines of ocean imps are areas of strength for firm, lightweight These spines are made of a weak mineral called calcium carbonate, which is like engineered pottery, yet the imp has a lot higher capacity to bear harm while getting weight or power. Li’s group tried this rule by squeezing the spines precisely, mimicking a similar sort of condition under which a designing clay could have to persevere.

The ocean imp spines twisted nimbly under the power put on them, rather than the horrendous disappointment of flow engineered clay cell solids. This “agile disappointment” conduct permits the ocean imp spines to endure harm with huge energy retention ability.

During this examination, Li’s group revealed a mystery that enabled the imp to stay intact during mechanical stacking.

Mysteries of the profound

“There are several mysteries in the primary elements of ocean imp spines. One is connected with the association of branches, “said Li. “The second is the size of the pores.”

Under a magnifying lens, Li’s group noticed a pattern of interconnected short branches. An organization of hubs keeps these branches intact, and one of the keys to the imp’s resilience is the harmony between the quantity of hubs and branches. That number is exactly right, since hubs with too many associated branches will make the design become weak and flimsy.

The hubs in the permeable design of ocean imp spines are associated with three branches overall, and that implies the organization of branches will go through a bowing prompted crack rather than a more disastrous extending actuated break.

The subsequent mystery lies in the size of the holes, or pores, between branches. The group found that the holes inside the permeable design of ocean imp spines are simply somewhat more modest than the size of the branches. This implies that once the branches crack, they can be secured quickly by these more modest openings. Broken branches stack on top of each other on the pores, making a thick locale that is as yet ready to support a load.

Ocean imps likewise have an unexpected surface morphology in comparison to engineered pottery. Made cell pottery has numerous tiny deformities across its surfaces and inside, making these materials more helpless to disappointment. This isn’t true with the ocean imp spine, which has a nearly glasslike surface, smooth down to the nanometer scale. Deserts are focuses from which harm can begin, and the absence of deformities implies an absence of areas inclined to disappointment.

Li showed this thought with a piece of paper. “At the point when you attempt to tear a whole piece of paper, the paper opposes tearing. Assuming you make a little tear along the edge of the paper, nonetheless, the tear will go on from that damaged point. “

With branches, pores, and a smooth surface in play, the lightweight ocean imp spines accomplish high strength and harm resilience by consistently conveying the pressure inside the design and retaining energy more effectively.

Making in the up and coming age of pottery

Having this information, could we at any point reproduce the perfection, absence of deformities, and the particular branch and hub structures expected to be gained by the ocean imp’s mysteries? On the grounds that the ongoing techniques for handling pottery aren’t exactly there, we can’t.

Pottery made artificially is commonly framed in a two-step process. The initial step is to make the shape, and the second is to fire the piece so the clay solidifies, which gives it the strength for which it is known. Potters follow this strategy when they make a pot and bake it in an oven. Similar cycles are used for 3D-printed pottery, where the 3D-printing step frames the shape and the subsequent firing is expected to create the final clay parts.

That terminating, or sintering, step is the most risky for reproducing the ocean imp’s microstructure on the grounds that the sintering system prompts the development of tiny deformities, thereby delivering low strength.

“In my lab, we are additionally keen on how creatures, for example, ocean imps, structure these normal clay cell solids,” said Li. “Ideally, one day, we can not just coordinate the material plan standards to bio-roused lightweight clay materials, yet in addition, the material handling techniques gained from normal frameworks.”

More information: Ting Yang et al, High strength and damage-tolerance in echinoderm stereom as a natural bicontinuous ceramic cellular solid, Nature Communications (2022). DOI: 10.1038/s41467-022-33712-z