Analysts at the Department of Energy’s Oak Ridge National Laboratory are training magnifying instruments to drive disclosures with a natural calculation, created at the lab’s Center for Nanophase Materials Sciences, that could direct forward leaps in new materials for energy innovations, detecting and registering them.

“There are so many expected materials, some of which we can’t learn by any means with traditional devices, that we need more effective and methodical ways to deal with plan and combine,” said Maxim Ziatdinov of ORNL’s Computational Sciences and Engineering Division and the CNMS. “We can utilize shrewd robotization to get to neglected materials as well as make a shareable, reproducible way to disclosures that poor people have recently been conceivable.”

The methodology, published in Nature Machine Intelligence, consolidates physical science and AI to mechanize microscopy tests intended to concentrate on materials’ practical properties at the nanoscale.

Utilitarian materials, which range from PCs and sun-based cells to counterfeit muscles and shape-memory materials, are receptive to upgrades like intensity or power and are intended to help both regular and emerging advances.Their extraordinary properties are attached to nuclear designs and microstructures that can be seen with cutting-edge microscopy. Nonetheless, the test has been to foster productive ways of finding districts of revenue where these properties arise and can be researched.

“There are so many potential materials, some of which we cannot examine at all with conventional instruments. We can employ smart automation to acquire previously unknown materials as well as build a shareable, reproducible path to previously unattainable findings.”

Maxim Ziatdinov of ORNL’s Computational Sciences and Engineering Division and the CNMS.

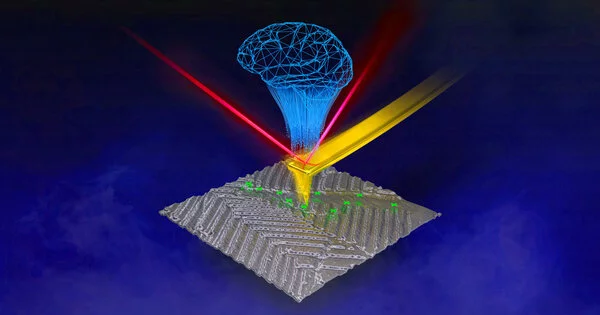

Filtering test microscopy is a fundamental instrument for investigating the connections between construction properties and useful materials. Instruments check the outer layer of materials with a molecularly sharp test to delineate the design at the nanometer scale—the length of one billionth of a meter. They can also recognize reactions to a variety of changes, providing insights into critical systems of polarization exchanging, electrochemical reactivity, plastic distortion, or quantum peculiarities.The current magnifying instruments can perform a point-by-point sweep of a nanometer square lattice, but the cycle can be extremely slow, with estimates gathered over days for a single material.

“In many cases, the intriguing actual peculiarities appear in a few spatial areas and are attached to explicit but obscure primary components.”While we commonly have a thought of what will be the trademark highlights of actual peculiarities we intend to find, pinpointing these locales of interest proficiently is a significant bottleneck, “said previous ORNL CNMS researcher and lead creator Sergei Kalinin, presently at the University of Tennessee, Knoxville. “We want to help magnifying instruments to look for districts with intriguing physical science effectively and in a way substantially more productive than playing out a network search.”

Researchers have gone to AI and man-made consciousness to conquer this test, yet ordinary calculations require enormous, human-coded datasets and may not save time eventually.

For a more intelligent way to deal with computerization, the ORNL work process integrates human-based actual thinking into AI techniques and uses tiny datasets—pictures obtained from under 1% of the example—as a beginning stage. The calculation chooses focal points in light of what it advances inside the investigation and on information from outside the examination.

As a proof of idea, a work process was shown utilizing examining test microscopy and applied to all contemplated ferroelectric materials. Ferroelectrics are utilitarian materials with a reorientable surface charge that can be utilized for registering, activating, and detecting applications. Researchers are keen on understanding the connection between how much energy or data these materials can store and the neighborhood area structure administering this property. The computerized exploration found the particular topological imperfections for which these boundaries are upgraded.

“The focal point is that the work process was applied to material frameworks recognizable to the examination local area and made a principal finding, something not recently known, rapidly — in that frame of mind, inside a couple of hours,” Ziatdinov said.

The results were significantly faster — by a large margin — than traditional work processes, and they addressed another course in savvy robotization.

“We needed to create some distance from preparing PCs solely on information from past analyses and, on second thought, show PCs how to think like analysts and learn on the fly,” said Ziatdinov. “Our methodology is propelled by human instinct and perceives that numerous material disclosures have been made through the experimentation of scientists who depend on their mastery and experience to think about where to look.”

ORNL’s Yongtao Liu was responsible for the specialized test of getting the calculation to run on a functional magnifying lens at the CNMS. “This is anything but an off-the-rack ability, and a great deal of work goes into associating the equipment and programming,” said Liu. “We zeroed in on filtering test microscopy, but the arrangement can be applied to other trial imaging and spectroscopy approaches open to the more extensive client local area.”

The diary article is distributed as “Exploratory revelation of design property connections in ferroelectric materials through dynamic learning.”