One of the main components in photonic chips or quantum chips is the optical waveguide. Because of restrictions in existing manufacturing strategies, it is difficult to effectively deliver waveguides with high accuracy control of the 3D cross-area shape and size. To determine this difficult issue, researchers at the University of Oxford have fostered another waveguide creation procedure that can quickly deliver waveguides on a chip with definitively controlled 3D cross-segments that likewise display changing conduct along the waveguide. The waveguides have been demonstrated with extremely low errors and demonstrate exceptional commitment for photonic or quantum chips.

Foundation

With the development of the semiconductor industry, the customary electronic coordinated circuit is moving toward its cutoff in data transmission and energy utilization. Compared with electronic coordinated circuits, photonic incorporated circuits show lower transmission misfortune, more extensive transfer speed, and more modest time delay. However, the rapid advancement of quantum innovation in recent years indicates that quantum chips will soon supplant a few parts of conventional electronic coordinated circuits.

It is notable that the essential unit of an electronic coordinated circuit is the semiconductor diode. Optoelectronic chips and quantum chips, like electronic integrated circuits, have their own fundamental components.Among these essential parts, the micron-scale optical waveguide is quite possibly the main component. In light of fleeting wave coupling, contiguous optical waveguides can understand programmable sign handling, giving key capabilities to quantum/photonic chips.

Micron-size optical waveguides have previously been limited to two-layered square, elliptic, and round cross-segments due to previous constraints on creation innovation.As of now, there are limited innovation choices that can effectively create waveguides with both low misfortune and exact 3D cross-segment variety. This forces numerous constraints on the functionality and proficiency of photonic and quantum chips.

The SPIM-WGs innovation

In another paper distributed in Light Science and Application, Dr. Bangshan Sun, Prof. Martin J. Corner, and a group of researchers at the University of Oxford, teamed up with Prof. Alina Karabchevsky of Israel, Prof. Alexander Jesacher of Austria, and Prof. Ian A. Walmsley of Imperial College London, have fostered another innovation named “SPIM-WGs.” With this procedure, optical waveguides with persistently factored 3D cross-segments can be effectively manufactured on a chip. Optical waveguides created in view of this innovation are analyzed in better presentation than customary waveguides and additionally bring a few new highlights, making them ready for future photonic and quantum chips.

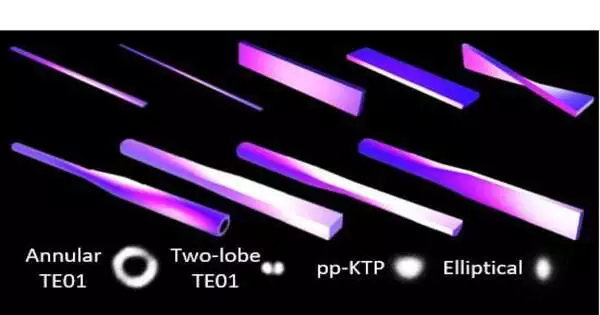

In view of versatile optics, the innovation’s greatest feature is that it can effectively deliver low-misfortune waveguides with variable cross-segments, like round, square, annular, or numerous other muddled shapes. The accuracy of controlling the cross-area in each hub can be measured in nanometers.For a solitary waveguide, the state of cross-segment can change along the actual waveguide. For models, they can bend, shift from square to round, or from round to ring molded, etc.

It is worth focusing on that the waveguide displays exceptionally low transmission misfortunes during the exact difference in morphology. In view of the glass substrate, the waveguide has a transmission loss of about 0.14 dB/cm, and that implies that just around 3% of the optical power is lost while sending 1 cm through the chip. Exploratory outcomes show that the additional transmission misfortune brought about by cross-area variety is practically unimportant.

The expenditure of time to make the waveguides is additionally essential. For a model, the conventional silica-on-silicon (SoS) strategy requires about a month or more to deliver waveguides from planning. In examination, SPIM-WGs can be delivered in practically no time, which gives an alternate degree of adaptability in prototyping and making.

Application potential

The main application of SPIM-WGs is optical mode change. In principle, SPIM-WGs can give the ability of optical mode change for any erratic shape, restricted simply by the diffraction restricted size of the manufacturing exacting attention. SPIM-WGs can, without much of a stretch, proselyte between Gaussian light modes, circular light modes, twofold curve TE01, and ring TE01 modes. These modes show up in an extensive variety of optoelectronic chips.

One of the most significant applications in mode transformation is between pp-KTP waveguides and single mode fiber, spanning quantum light sources and quantum chips. As of now, the pp-KTP waveguide in a quantum light source must be straightforwardly associated with a solitary mode fiber, which loses around 25–30% of the light force. Assuming the mode change waveguide made by SPIM-WGs is utilized for the crossing over, it is normal that the light power misfortune can be diminished by under 10%. This would have incredible effects on the productivity of most quantum chips.

What’s more, in light of the usefulness of mode change, SPIM-WGs can be associated with a solitary mode fiber with coupling productivity of up to 95%. This permits SPIM-WGs gadgets to be handily joined with most existing photonic gadgets.

It is found that waveguides with rectangular cross-areas turned at 90 degrees might be utilized to control the polarization of light. This also holds tremendous promise for some photonics and quantum applications.

More information: Bangshan Sun et al, On-chip beam rotators, adiabatic mode converters, and waveplates through low-loss waveguides with variable cross-sections, Light: Science & Applications (2022). DOI: 10.1038/s41377-022-00907-4

Journal information: Light: Science & Applications