Raman spectroscopy, an optical microscopy method, is a non-damaging compound examination strategy that gives rich sub-atomic unique mark data about synthetic design, stage, crystallinity, and atomic connections. The method depends on the connection of light with compound bonds inside a material. Nonetheless, since light is a wave, an optical magnifying lens can’t determine exactly a portion of the frequency of the light episode on the example. This is known as “as far as possible,” which forestalls Raman spectroscopy and other optical microscopy methods from coming to nanoscale goals.

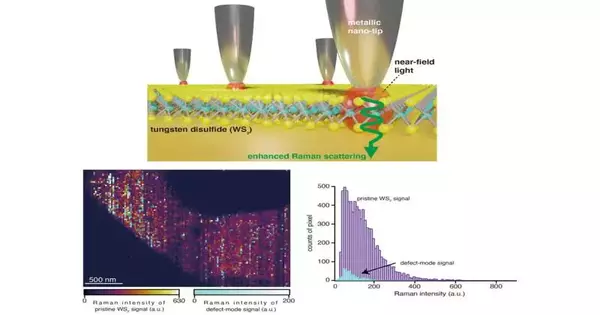

To work on the spatial goal, another method called “tip-improved Raman spectroscopy” (TERS) was created, which can arrive at spatial goals beneath as far as possible. In TERS, a metallic nano-sized tip keeps the light at a nano-sized volume simply over the example. The light interacts with the example atoms on a superficial level, and the imaging is performed by examining the dispersed light.

TERS has been effectively used to examine compound pieces and surface deformities in examples at nanoscale goals. In any case, during imaging, the nanotip will in general float because of undeniable thermal and vibrational changes under surrounding conditions, making either the example be out-of-concentration or misalignment between the nanotip and central spot, or both. This causes extensive bends in the dispersed signs. To keep away from this, TERS imaging should be finished inside a period window of 30 minutes, a limitation that forestalls imaging of any example bigger than 1 m2 with a nanoscale goal.

“Without considerable loss of optical signal, our innovative optical nano-imaging technology enables characterization of defect analysis in large-sized WS2 layers at a high pixel resolution down to 10 nm.”

Dr. Kato.

In another review distributed in Science Advances, an examination group from Japan, led by Dr. Ryo Kato, an assigned Assistant Professor at the Institute of Post-LED Photonics at Tokushima University, and Associate Professor Takayuki Umakoshi and Professor Prabhat Verma from Osaka University, has now evolved, interestingly, a steady TERS framework that isn’t restricted to a short imaging time window. The group showed its capacity by effectively imaging nanoscale deserts over a period of 6 hours in a micrometer-sized, two-layered (2D) tungsten disulfide (WS2) film—a material usually utilized in optoelectronic gadgets. “Our new optical nano-imaging framework empowers portrayal of deformity examination in huge measured WS2 layers at a high pixel goal down to 10 nm with no critical loss of optical signal,” says Dr. Kato.

To make up for the floats’ overstretched periods, the group fostered an input framework that tracks the removal of the shone light source and corrects the place of the center plane likewise. The central point of the light source is followed by estimating the removal of a reflected laser guide bar coordinated into the magnifying lens. The center is then settled with a piezo-controlled objective scanner at whatever point the framework detects a float or an adjustment of the central place of the light source.

To settle the nanotip, the group planned a laser-checking helped tip float pay framework. For this situation, galvano-scanners take pictures of the laser spot around the metallic nanotip similarly as it moves toward the example surface. This picture shows up as a splendid spot and demonstrates the place of the nanotip. When the estimation at a specific pixel has been done, the picture of the laser spot around the nanotip is caught once more. The laser spot is then moved to match the new position of the nanotip in this picture. The cycle goes on all through the imaging system, guaranteeing the nanotip stays in a steady position.

By executing these remedies, the group had the option to picture a 2D sheet of WS2 (see picture above) with a sweep area of 1 4 m2. With a 12 times longer imaging time window than that of regular imaging, they could identify novel deformities missed in ordinary TER imaging. They also showed that the deformity thickness on a bigger WS2 test (similar to gadget scales) was higher than that detailed for more modest examples.

The review could pave the way for exact, high-goal imaging of optoelectronic gadgets as well as natural examples. “Not only can our new float repaid TERS microscopy assess surface properties of gadget materials better, but it also allows us to concentrate on natural cycles like the system basic the development of illnesses.” This, thus, could assist with creating novel clinical techniques and treatments, “says Dr. Umakoshi.

More information: Ryo Kato et al, Ultrastable tip-enhanced hyperspectral optical nanoimaging for defect analysis of large-sized WS2 layers, Science Advances (2022). DOI: 10.1126/sciadv.abo4021. www.science.org/doi/10.1126/sciadv.abo4021