Tom Stavert is a co-Ph.D. In the journal RSC Sustainability, a researcher from Sheffield and Strathclyde examines how combining computational modeling with green chemical principles can promote sustainable manufacturing.

A Sheffield-Strathclyde research team recently released a new paper that highlights novel research techniques that are essential to the decarbonization of industry.

Graduate student researcher Tom Stavert holds a Ph. D., a joint initiative between the Universities of Sheffield and Strathclyde, under Prof. Together with Dr. Robert Pilling, Siddharth Patwardhan, and Dr. Miguel Jorge, all three contributed to the new paper.

“Being a part of a collaborative Ph.D. project has provided me with a terrific perspective on the value of using a multi-disciplinary approach to tackling research difficulties since it incorporates both experimental and computational methodologies.”

Tom Stavert is a postgraduate researcher whose Ph.D.

Tom’s research focuses on combining cutting-edge experimental and computational techniques to create sustainable nanomaterials.

The result of his recent research is an article in RSC Sustainability titled “Unlocking the holy grail of sustainable and scalable mesoporous silica using computational modeling.”

Drug delivery to patients, gas separation, catalysis, and biosensors—the latter of which can be used for disease monitoring, among other things—are just a few uses for ordered mesoporous silica (OMS).

Despite the fact that OMS was discovered 30 years ago, it is currently not possible to produce such materials sustainably due to the high energy and resource requirements, extreme pH, harsh, toxic chemicals, and polluted water requirements.

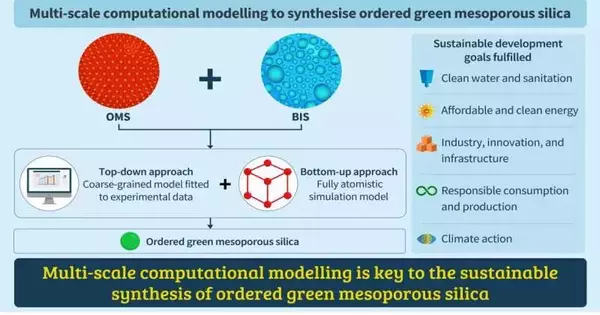

Designing high-value mesoporous silica under more environmentally friendly conditions using bio-inspired techniques is a fantastic alternative that enables both sustainable and cost-effective scale-up. It is currently difficult to produce products that are on par with the quality of conventional mesoporous silica because the synthesis of bio-inspired silica (BIS) is not fully understood.

As a result, this article summarizes significant discoveries in the development of OMS and BIS synthesis, with an emphasis on the difficulties in creating scalable production methods for these materials. It also highlights recent successes in using computational modeling to enhance the mechanistic understanding of syntheses and how modeling can be applied to the predictive design of BIS.

Material discovery and sustainable manufacturing could be revolutionized by fusing computational modeling with the ideas of green and sustainable chemistry. In some circumstances, this strategy can result in a two-order reduction in production costs.

Future results from this work will be consistent with a number of the Sustainable Development Goals (SDGs) of the United Nations, including SDG 6 (clean water and sanitation), SDG 7 (affordable and clean energy), SDG 9 (industry, innovation, and infrastructure), SDG 12 (responsible consumption and production), and SDG 13 (climate action).

Tom recently published a piece in which he said, “Being a part of a collaborative Ph.D. Considering that this project combines both experimental and computational methods, it has really helped me understand the value of using a multidisciplinary approach to address research challenges.

In this article, we demonstrate how, by combining seemingly unrelated lines of inquiry, researchers with various specialties can contribute their knowledge to produce fresh and efficient research methodologies. Decarbonizing industry and successfully combating climate change depend on this combined strategy.”.

More information: Tom Stavert et al, Unlocking the holy grail of sustainable and scalable mesoporous silica using computational modelling, RSC Sustainability (2023). DOI: 10.1039/D3SU00019B