Glass is being utilized in a more extensive scope of superior execution applications, including those for purchasers and industry, military and aviation gadgets, coatings, and optics. On account of the outrageous accuracy requested for use in items, for example, cell phones and stream airplanes, glass substrates should not change their shape during the assembly process.

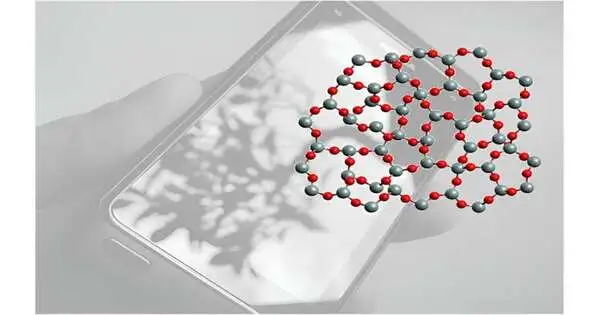

Corning Consolidated, a producer of imaginative glass, earthenware production, and related materials, focuses intently on concentrating on the strength of various sorts of glass. As of late, Corning analysts have found that understanding the soundness of the rings of molecules in glass materials can assist them with anticipating the presentation of glass items. This capacity is significant in light of the fact that the most commonly utilized glass is silicate glass, which comprises various sizes of nuclear rings associated with three aspects.

Directing neutron dispersing tests at the Branch of Energy’s Oak Edge Public Research facility, ORNL and Corning researchers found that as the quantity of more modest, less-stable nuclear rings in a glass builds, the shakiness, or fluid delicacy, of the glass likewise increases.

The consequences of the neutron tests, distributed in Nature Correspondences, uncover an unmistakable connection between the medium-range nuclear ring construction of a silicate glass and its fluid delicacy. The thickness of the fluid glass changes extensively when it is cooled to the glass progress temperature. A more delicate fluid will have a bigger consistency change with a given temperature change.

“Previously, scientists had been unable to determine the mechanism governing glass transitions. It was unclear why some forms of glass solidified sooner or slower.”

Said Ying Shi, the corresponding author of the study’s paper and research associate at Corning.

“Beforehand, the component driving glass advances had evaded researchers,” said Ying Shi, the co-creator of the review’s paper and exploration partner at Corning. “There was no unmistakable comprehension with regards to why a few sorts of glass hardened quicker or more slowly.”

Shi and her teammates from Corning, the College of California, Los Angeles, and the College of Oxford worked with the Migrant neutron diffractometer beamline researchers at ORNL’s Spallation Neutron Source to study aluminosilicate glass, which is generally utilized by industry.

Utilizing an as-of late evolved and approved neutron dissipating information examination device, RingFSDP, the group recognized key examples in the gathered information that uncovered the connection between the fluid delicacy in the glass and its nuclear ring strength.

RingFSDP is a free, open-source program created by Corning and ORNL researchers to concentrate on the nuclear ring designs of silicate glass. It determines ring-size conveyances in silicate glass from the state of the principal sharp diffraction top in the neutron diffraction information.

“Interfacing the glass progress temperature to the fundamental primary elements of a glass will essentially affect the glass plan and creation,” said Douglas Allan, the paper’s co-creator and an exploration individual at Corning. “Our work shows a reasonable connection between the nuclear ring design of a glass and its glass’s changing temperature range and, in this way, the presentation elements of the glass.”

More information: Ying Shi et al, Revealing the relationship between liquid fragility and medium-range order in silicate glasses, Nature Communications (2023). DOI: 10.1038/s41467-022-35711-6