A thermal cloak that passively regulates the temperature of electric vehicles could be a novel way to keep them cool in the summer and warm in the winter. This thermal cloak’s primary function would be to insulate the vehicle’s interior, reducing heat transfer between the inside and outside environments.

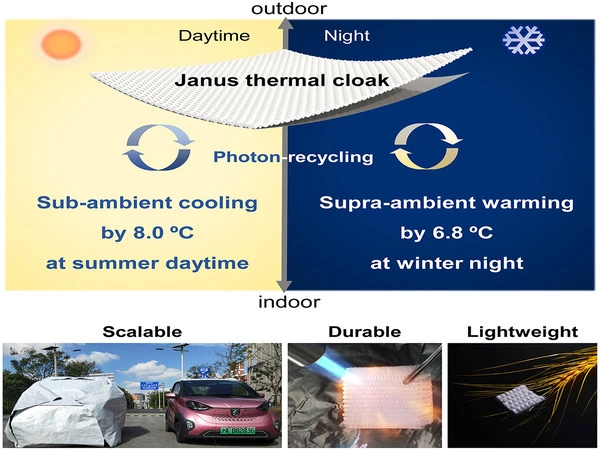

When an electric vehicle is parked outside, the temperature can fluctuate dramatically from day to night and season to season, causing the battery to deteriorate. Researchers developed an all-season thermal cloak that can cool an electric vehicle by 8°C on a hot day and warm it by 6.8°C at night to dampen these fluctuations and extend the battery’s lifespan.

The cloak, which is primarily made of silica and aluminium, can do so passively without any outside energy input and can function in either hot or cold weather. This prototype was described on July 11 in Device, a new application-oriented sister journal to Matter, Joule, and Cell.

“The thermal cloak is like clothes for vehicles, buildings, spacecrafts, or even extraterrestrial habitats to keep cool in summer and warm in winter,” says senior author Kehang Cui, a materials scientist at Shanghai Jiao Tong University.

The thermal cloak is like clothes for vehicles, buildings, spacecrafts, or even extraterrestrial habitats to keep cool in summer and warm in winter. The cloak works in the same way that the earth cools down, through radioactive cooling.

Kehang Cui

The cloak isolates the car – or any other object beneath it – from the surrounding environment to dampen natural temperature fluctuations. The cloak is made up of two layers: an outer layer that effectively reflects sunlight and an inner layer that traps heat inside. Whatever heat is absorbed by the outer layer is emitted in such a way that it can be easily dissipated into space. This design has earned it the moniker Janus thermal cloak, after the two-faced Roman god Janus.

“The cloak works in the same way that the earth cools down, through radiative cooling,” Cui explains. “The atmosphere covers the earth, and the atmosphere is transparent to a certain range of electromagnetic energy that we emit.”

While this process is preferable in the summer, it will make the car colder in the winter. “You have to develop something that can turn on and off by itself without external energy input, and that’s extremely difficult,” Cui says.

Cui and his colleagues created the cloak to automatically counteract this effect during the winter. The cloak uses a phenomenon known as “photon recycling,” in which any energy trapped beneath the cloak bounces back and forth between the car and the cloak rather than escaping to the surroundings outside.

The researchers tested the thermal cloak’s performance on electric vehicles parked outside in Shanghai under typical ambient conditions. At midday, the cabin temperature of an uncovered car reached 50.5°C, while the cabin temperature of a cloak-covered car reached 22.8°C – 27.7°C lower than the uncovered car and 7.8°C lower than the outside temperature. At midnight, the covered car remained 6.8°C warmer than the outside temperature, never dropping below 0°C.

“This is the first time we were able to achieve warming above the ambient temperature by nearly 7°C during winter nights,” Cui says. “This is also somewhat surprising to us; there is no energy input or sunlight, but we can still get warming.”

The cloak’s outer layer is made of thin silica fibres that have been coated in flakes of hexagonal boron nitride, a ceramic material similar to graphite that increases the solar reflectivity of the fibres. These fibres are then braided and woven into a fabric and adhered to an inner layer of aluminium alloy.

The cloak was purposefully designed by the team to facilitate future production scaling. Thinner silica fibres, for example, would have increased solar reflectivity, but they would be weaker and couldn’t be made using existing high-volume, industrial-level production techniques. Furthermore, the materials used, such as aluminium, silica, and boron nitride, are all low-cost and contribute to the cloak’s lightweight, durability, and fire resistance.