Printing objects from plastic precisely, rapidly, and cheaply is the objective of numerous 3D printing processes. Nonetheless, speed and a high goal stay a mechanical test. An exploration group from the Karlsruhe Foundation of Innovation (Pack), Heidelberg College, and the Queensland College of Innovation (QUT) has progressed significantly toward accomplishing this objective. It fostered a laser printing process that can print micrometer-sized parts quickly. The global group published the work in Nature Photonics.

Stereolithography 3D printing is presently one of the most famous added substance producing processes for plastics, both for private and modern applications. In stereolithography, the layers of a 3D item are extended individually into a holder loaded up with tar. The tar is relieved by UV light. Nonetheless, past stereolithography techniques are slow and have too low a goal. Light-sheet 3D printing, which is utilized by the unit scientists, is a quick and high-goal elective.

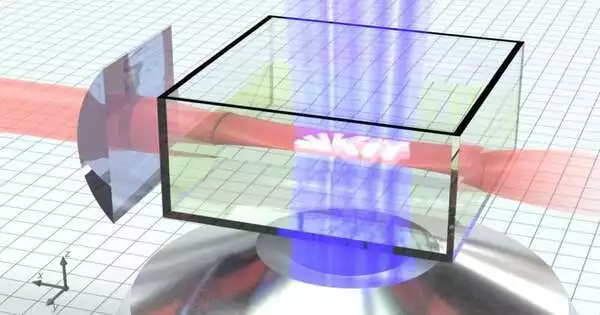

3D printing with two tones in two phases.

In light-sheet 3D printing, blue light is projected into a holder loaded up with a fluid tar. The blue light pre-enacts the tar. In a subsequent stage, a red laser bar gives the extra energy expected to fix the tar. In any case, 3D printing can rapidly print gums that rapidly get back from their pre-enacted state to their unique state. At that time, might the following layer at any point be printed?

“We could even use LEDs instead of lasers in our 3D printer with more sensitive resins. Ultimately, we want to be able to print centimeter-sized 3D structures while maintaining micrometer resolution and high printing speeds.”

Professor Martin Wegener of APH.

Subsequently, the return time directs the holding up time between two progressive layers and hence the printing speed. “For the gum we utilized, the return time was under 100 microseconds, which is considered high printing speeds,” says first creator Vincent Hahn from Unit’s Foundation of Applied Physical Science (APH).

Micrometer-sized structures in only the squint of an eye.

To exploit this new gum, the scientists fabricated a unique 3D printer. In this printer, blue laser diodes are utilized to extend pictures into the fluid tar, utilizing a high-goal show with a high edge rate. The red laser is framed into a slim “light sheet” bar and crosses the blue bar upward in the sap.

For example, with this plan, the group had the option to 3D print micrometer-sized parts in a couple hundred milliseconds, for example. Nonetheless, it shouldn’t stop there: “With additional touchy gums, we might involve LEDs rather than lasers in our 3D printer,” says Teacher Martin Wegener of APH. “At last, we need to print 3D designs that are centimeters in size while keeping up with our micrometer goal and high printing speeds.”

More information: Vincent Hahn et al, Light-sheet 3D microprinting via two-colour two-step absorption, Nature Photonics (2022). DOI: 10.1038/s41566-022-01081-0

Journal information: Nature Photonics