With gas prices taking off and food costs squeezing family spending plans, an interdisciplinary group of scientists at WPI is taking a gander at ways of utilizing food waste to make a sustainable and more reasonable fuel swap for oil-based diesel. The work, led by Chemical Engineering Professor Michael Timko, is definite in another paper in the journal iScience.

“By making biodiesel through this strategy, we’ve demonstrated the way that we can bring the cost of gas down to $1.10 per gallon, and possibly even lower,” said Timko.

The Environmental Protection Agency gauges that, in 2018, in the United States, around 81% of family food — around 20 tons — wound up in landfills or burning offices. Food waste is likewise a significant supporter of environmental change: whenever it’s set in landfills, it radiates methane, an ozone-harming substance.

Timko said, “Changing over food waste to diesel likewise can possibly balance up to 15.3 million tons of CO2 consistently, bringing down ozone-harming substance outflows in the United States by 2.6%.”

The work is essential for a long-term project upheld by the Department of Energy, the National Science Foundation, and the Massachusetts Clean Energy Center, and it expands on and refines research recently distributed in 2018. Timko and his group have now centered around figuring out how to make the change cycle simpler to scale and bring to the business market.

“Food waste conversion to diesel has the potential to offset up to 15.3 million tons of CO2 per year, cutting greenhouse gas emissions in the United States by 2.6%.”

Chemical Engineering Professor Michael Timko

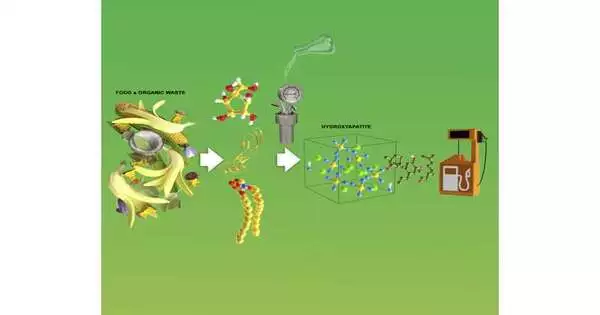

To make the fuel, the scientists utilized a cycle called aqueous liquefaction, which utilizes intensity and water to separate the food squander into a fluid. A strategy has been broadly utilized in changing different materials into biofuel, including green growth. Nonetheless, utilizing food squander eliminates the need to develop and develop green growth — a costly and tedious cycle — while likewise prompting comparable outcomes for how much fuel that is removed. The group likewise utilized an impetus made of a normally occurring mineral tracked down in unresolved issues, but got 30% more energy out of the food squander.

Aide Professor Andrew Teixeira and Ph.D. understudy Heather LeClerc assumed key parts in the examination too. LeClerc spent the previous year leading examinations in Denmark as part of a Fulbright grant, and he is currently part of a three-year NSF graduate exploration partnership.

For this most recent work on food waste and biofuel, LeClerc collaborated with the Woods Hole Oceanographic Institute on Cape Cod to gain a better understanding of the biocrudes the WPI group was developing, utilizing equipment that Woods Hole scientists regularly use to figure out what an oil slick means for the sea climate and how to transform it over time.

The analysts will proceed with their endeavors to refine the fuel much further and foster ways of utilizing the cycle to make home heating oil and marine diesel to drive ships.

More information: Heather O. LeClerc et al, Hydroxyapatite catalyzed hydrothermal liquefaction transforms food waste from an environmental liability to renewable fuel, iScience (2022). DOI: 10.1016/j.isci.2022.104916

Journal information: iScience