Wooden items are normally made by cutting, squeezing, or bowing. That is so old school! Today, researchers will demonstrate how level wooden shapes expelled by a 3D printer can be modified to self-transform into complex 3D shapes. Later on, this method could be utilized to make furniture or other wooden items that could be sent level to an objective and then dried to frame the ideal last shape.

The analysts will present their outcomes at the fall meeting of the American Chemical Society (ACS).

In nature, plants and a few creatures can change their own shapes or surfaces. Indeed, even after a tree is chopped down, its wood can change shape as it dries. It recoils unevenly and twists due to varieties in fiber direction inside the wood. “Twisting can be a snag,” says Doron Kam, an alumni understudy who is introducing the work at the gathering, “yet we figured we could attempt to grasp this peculiarity and bridle it into an alluring transforming.”

“Warping may be a challenge, but we felt we could attempt to understand it and harness it to create a desired morphing.”

Doron Kam,

Dissimilar to a few normal items, fake designs can’t commonly shape themselves, says Eran Sharon, Ph.D., one of the task’s key examiners. Yet, researchers lately have started printing level sheets that could frame themselves into 3D shapes after a boost, for example, an adjustment of temperature, pH or dampness content, says Sharon. Nonetheless, these self-transforming sheets were produced using engineered materials, for example, gels and elastomers, he notes.

“We needed to return to the beginning of this idea, to nature, and do it with wood,” says Sharon. He and Kam — as well as Shlomo Magdassi, Ph.D., and Oded Shoseyov, Ph.D., the other head examiners who took on this test with Ido Levin, Ph.D., who was an alumni understudy at that point — are at The Hebrew University of Jerusalem.

A couple of years prior, the group fostered a harmless to the ecosystem water-based ink made out of wood-squander microparticles known as “wood flour” blended in with cellulose nanocrystals and xyloglucan, which are normal folios removed from plants. The scientists then started involving the ink in a 3D printer. They as of late found that how the ink is set down, or the “pathway,” directs the transforming conduct as the dampness content vanishes from the printed piece. For example, a level plate printed as a progression of concentric circles dries and therapists to frame a seat like design suggestive of a Pringles potato chip, and a plate printed as a progression of beams exuding from a main issue transforms into a vault or cone-like construction.

The team discovered that changing the print speed can also limit the final state of the item.That is on the grounds that shrinkage happens opposite to the wood strands in the ink, and print speed changes the level of arrangement of those filaments. A more slow rate leaves the particles more haphazardly situated, so shrinkage happens every which way. Quicker printing adjusts the strands to each other, so shrinkage is more directional.

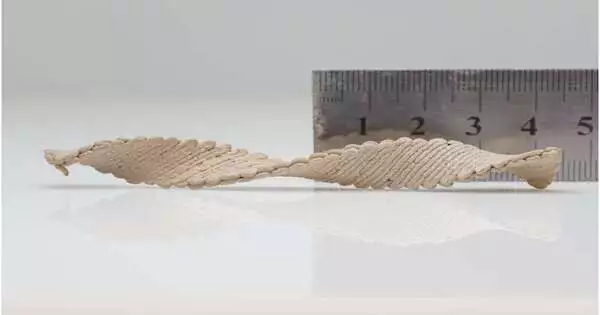

The researchers figured out how to program the print speed and pathway to accomplish various last shapes. They found that stacking two rectangular layers that are imprinted in various directions yields a helix subsequent to drying. In their most recent work, they found that they can program the printing pathway, speed, and stacking to control the particular course of shape change—for example, whether square shapes bend into a helix that twists clockwise or counterclockwise.

Further refinement will permit the group to join the seats, vaults, helices and other planned themes to create objects with muddled last shapes, like a seat. Finally, it very well may be feasible to make wood items that are sent level to the end client, which could reduce delivery volume and expenses, Kam says. “Then, at the objective, the item could twist into the construction you need.” According to Sharon, it may eventually be possible to allow the technology for home use, allowing customers to design and print their own wooden items using a standard 3D printer.

The group is likewise investigating whether the transforming system could be made reversible. “We desire to demonstrate the way that, under certain circumstances, we can make these components responsive — to dampness, for instance — when we need to change the state of an item once more,” Sharon says.

More information: Wood warping by 3D printing, ACS Fall 2022. www.acs.org/content/acs/en/mee … tings/fall-2022.html