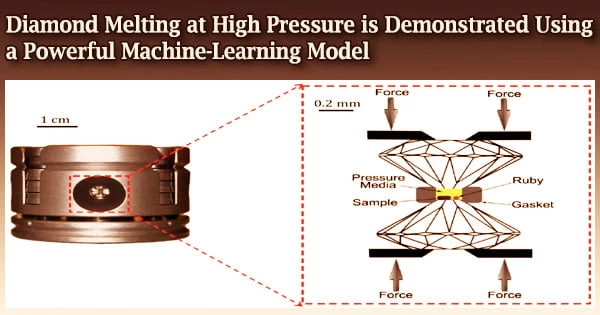

The melting of diamond when compressed by severe pressures and temperatures has been recorded by a Sandia National Laboratories supercomputer simulation model dubbed SNAP, which swiftly anticipates the behavior of billions of interacting atoms.

In SNAP (Spectral Neighbor Analysis Potential) simulations, the rigid carbon lattice of the toughest known substance on Earth cracks, melts into amorphous carbon, and subsequently recrystallizes at several million atmospheres.

The findings could contribute in the study of the interior structure of carbon-based exoplanets, as well as nuclear fusion attempts that use polycrystalline diamond capsules.

A high-accuracy SNAP model from Sandia National Laboratories is used in this multi-billion atom simulation of shockwave propagation into initially uncompressed diamond (blue) to predict that the final state (orange) is formed by recrystallization of amorphous cracks (red) that take shape in the light blue, green, and yellow compressed material.

Designing novel materials and implications for giant planets

“We can now study the response of many materials under the same extreme pressures,” said Sandia scientist Aidan Thompson, who originated SNAP. “Applications include planetary science questions for example, what kind of impact stress would have led to the formation of our moon. It also opens the door to design and manufacture of novel materials at extreme conditions.”

Extreme pressures and temperatures have an impact on materials, which is significant for creating interior models of big planets. In terrestrial studies, powerful DOE facilities like Sandia’s Z machine and Lawrence Livermore National Laboratory’s National Ignition Facility can mimic near-identical conditions of these planets, allowing for close analyses of dramatically compressed materials.

We can now study the response of many materials under the same extreme pressures. Applications include planetary science questions for example, what kind of impact stress would have led to the formation of our moon. It also opens the door to design and manufacture of novel materials at extreme conditions.

Aidan Thompson

However, due to limits in diagnostics at the atomic level, even these incredibly powerful tools are unable to pinpoint critical microscopic causes of change under these high conditions.

“Only computer simulations can do that,” said Thompson.

Gordon Bell paper finalist is about ‘a micron-sized hunk of compressed diamond’

The simulation was described in a technical paper that was chosen as a finalist for the Gordon Bell Award, which is awarded annually by the Association of Computing Machinery. Prof. Ivan Oleynik of the University of South Florida led the diamond-specific modeling, which took only a day on the Summit supercomputer (the fastest in the US) at Oak Ridge National Laboratory.

The joint team includes software developers from the Department of Energy’s National Energy Research Scientific Computing Center and the NVIDIA Corporation, in addition to Sandia and USF.

According to Thompson, the team’s simulations used SNAP, one of the top machine-learning descriptions of interatomic interactions, to describe and address a critical problem.

“We created gigantic simulations of a micron-sized hunk of compressed diamond,” said Thompson. “To do this, we track the motion of billions of atoms by repeatedly calculating the atomic forces over very many, exceedingly tiny, intervals of time.”

Machine-learning bridged with quantum mechanical calculations

SNAP created a surrogate model that reliably reproduced the right atomic forces using machine learning and other data science techniques. These were estimated using quantum mechanical calculations with great precision, which are only possible for systems with a few hundred atoms.

After that, the surrogate model was scaled up to predict forces and accelerations in systems with billions of atoms. All local atomic structures that appeared in large-scale simulations were well-represented in small-scale training data, which is a need for accuracy.

According to Thompson, the performance improvement of the program to run efficiently on GPU-based supercomputers like Summit was another crucial aspect of the final solution.

“Since 2018, just by improving the software, we have been able to make the SNAP code over 30 times faster, shortening the time for these kinds of simulations by 97%. At the same time, each generation of hardware is more powerful than the last. As a result, calculations that might have until recently taken an entire year can now be run in a day on Summit.”

Run time shortened by 97 percent

“Since supercomputer time is expensive and highly competitive,” said Thompson, “each shortening of SNAP’s run time saves money and increases the usefulness of the model.”

Stan Moore and Mitchell Wood, both of Sandia, made significant contributions to the SNAP model and the remarkable performance increases.

The optimized software for running SNAP on supercomputers is included in Sandia’s LAMMPS (https://www.lammps.org/) molecular dynamics code’s open-source distribution. The Sandia FitSNAP software (https://github.com/FitSNAP/FitSNAP) for creating new SNAP models is also open source.

Sandia’s Laboratory Directed Research and Development program helped build the first version of SNAP in 2012. The DOE Exascale Computing Project, a partnership effort of the US Department of Energy Office of Science and the National Nuclear Security Administration, has been supporting software improvement since 2017.