Traditional robots, such as those used in assembly, can lift heavy loads and definitively rehash mechanized processes.Yet, they are excessively unbending and cumbersome for sensitive work and connection with people. Advanced delicate mechanics is concerned with the advancement of robots made of delicate, natural materials and adaptable specialized parts.Materials specialists at Kiel College have now developed an original, delicate conductive material.

Not at all like ordinary delicate channels, it shows astoundingly stable electrical properties even upon disfigurement. The justification for this is the extraordinary construction of the material and a nanoscopic protective film covering. The examination group distributed its outcomes in the recent issue of the diary, “Progressed Useful Materials.”

Steady electrical opposition in any event, during disfigurement

People and creatures, unlike traditional robots, can perform fluid and fine developments and adapt them to their current situation. As a result, advanced mechanics rely on versatile, natural materials made of carbon rather than regular, inflexible metals. Likewise, delicate robots need versatile electrical conduits for communication between their sensors and actuators.

“Of course, traditional metal conductors transmit electricity effectively, but they are too rigid for flexible components. They vary electrical resistance when deformed, which affects their usage in soft robotics.”

Dr. Fabian Schütt, the head of the junior research group Multiscale Materials Engineering.

“Regular conduits made of metal direct power well, obviously; however, they are excessively unbending for adaptable parts. Upon misshapening, they change their electrical opposition, and this influences their utilization in delicate mechanical technology,” says Dr. Fabian Schütt, the top of the lesser examination bunch Multiscale Materials Designing at the Seat of Useful Nanomaterials at Kiel College.

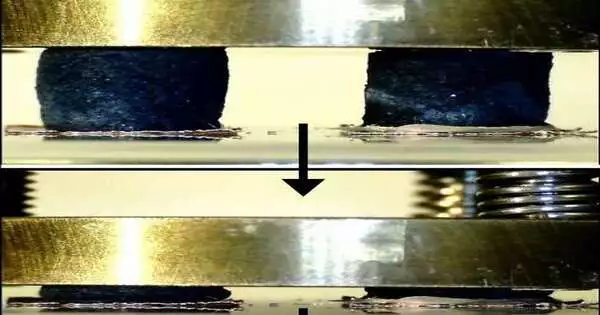

Conversely, the obstruction of the material, which Schütt developed with associates at the Foundation of Materials Science at Kiel College, stays consistent when it is distorted. “Both the underlying electrical and mechanical properties are maintained during long-term cycling, even after 2000 cycles at half pressure,” says Igor Barg, a doctoral specialist at the Seat for Multicomponent Materials and the article’s lead author.

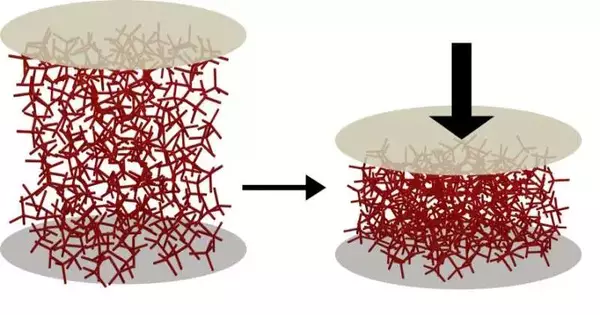

By joining different skills inside the Need Exploration Region KiNSIS (Kiel Nano, Surface, and Point of Interaction Study) of Kiel College, they made a material made of fine wires that seems to be a dull wipe. The wires consist of interconnected microtubes made of an electrically conductive polymer. This fragile organizational structure makes the material super light and simultaneously incredibly flexible.

Credit: Kiel College

Nanoscopic protection film safeguards the electrical properties of the material.

“Stretchable, wipe-like guides have proactively been explored for a considerable length of time. “In any case, when they are distorted, their obstruction likewise changes because of the supposed piezoresistive impact,” Barg makes sense of. To avoid this impact, the researchers coated their material with a non-conductive, nanoscopic thin film of Polytetrafluorethylene (PTFE).

“You can consider it an exemplary power link,” says Barg. The layer keeps the wires from coming into direct contact with one another during pressure and making new electrically conductive paths. As a result, even with massive misshapenings, the opposition remains consistent.The protection additionally works on the mechanical soundness of the wires and shields their electrical properties from outer impacts like dampness.

To cover this profoundly permeable system structure, an exceptional procedure is required. Dr. Stefan Schröder is at the top of the lesser-explored bunch of Useful CVD Polymers at the Seat for Multicomponent Materials and works with the newly started synthetic fume affidavit (iCVD).

This allows for the conformal coverage of even complex design and surface materials:When various gases are combined in a reactor, a synthetic response occurs, and a thin polymer film begins to form on the material to be.”Because this covering is only a couple of nanometers thick, the wires remain flexible, and the overall weight of the material barely expands,” Schröder explains.

Mechanical pressure tests show how the covering (left) further develops the flexibility contrasted with a similar material without the covering (right). (Scale in blue: 6 mm.) Credit: Igor Barg et al., Adv. Funct. Mater. 2023, 2212688 (CC BY 4.0)

Applications in clinical innovation are likewise possible.

“This model demonstrates very well how we can use nanoscale covering to explicitly change the properties of our system structures, which really depend on a few cubic centimeters in size, and even create completely new capabilities,” Schütt says.

“By consolidating our strategies, different applications, including business ones, may be conceivable later on, for instance in clinical innovation or energy stockpiling,” adds Schröder. They currently need to examine these conceivable outcomes in additional joint examination projects.

More information: Igor Barg et al, Strain‐Invariant, Highly Water Stable All‐Organic Soft Conductors Based on Ultralight Multi‐Layered Foam‐Like Framework Structures, Advanced Functional Materials (2023). DOI: 10.1002/adfm.202212688