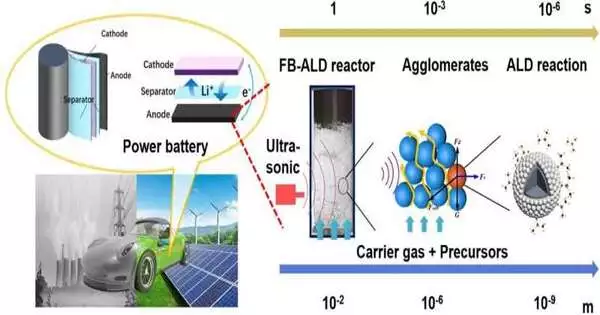

Surface change of miniature nanoparticles at the nuclear and near nuclear scales is vital to their applications in various fields, like energy stockpiling, catalysis, sensors, and biomedicine. To meet the business necessities here, it is vitally important to foster high-volume assembling of molecularly exact coatings on particulate materials. As a high-level outrageous assembling strategy, nuclear layer statement (ALD) is a slim film testimony technique which offers sans-pinhole films with exact thickness control at the angstrom level and uncommon homogeneity on complex designs. Fluidized bed ALD (FB-ALD) has shown extraordinary potential in molecularly ultrathin films on a lot of particles.

In another paper distributed in the International Journal of Extreme Manufacturing, a group of scientists, led by Prof. Rong Chen from the State Key Laboratory of Digital Manufacturing Equipment and Technology, School of Mechanical Science and Engineering, Huazhong University of Science and Technology, China, have completely examined the impact of ultrasonic vibration on the hydrodynamics and the molecule agglomeration conduct in a FB-ALD reactor through CFD-DEM recreation. The bed pressure drops and extensions, liquid fierce motor energy, dispersion of molecule speeds, strong volume parts, as well as the agglomerate sizes are introduced to portray the fluidization quality. Various amplitudes and frequencies of ultrasonic vibrations are examined to track down the ideal circumstances for upgrading the fluidization quality and the covering proficiency of the FB-ALD process.

To examine the impact of ultrasonic vibration on the overall fluidization way of behaving, a common ultrasonic vibration with a recurrence of 20 kHz and a sufficiency of 20 m is applied to the FB after the fluidization arrives at a consistent state. With the onset of the ultrasonic vibration, the speed of the particles near the vibrating wall increments right away. The number of particles moving at high speeds increases, resulting in more molecule collisions.bed level increments slowly as time increments, which infers that the ultrasonic vibration can really advance molecule scattering. Besides, directing is likewise decreased by the ultrasonic field. These upgrades of fluidization ways of behaving are useful to the molecule covering process, since the antecedent atoms can diffuse quicker and more consistently into the agglomerates, thus expanding the general covering proficiency.

Liquid fierce movement is the essential justification for particles to accomplish arbitrary movement, and choppiness motor energy is the vital element for assessing the breakage energy for molecule agglomerates. Without the ultrasonic vibration, the choppiness of motor energy is tiny, and it stays unaltered. Nonetheless, when the ultrasonic vibration is applied, the greatest choppiness in motor energy increments strongly. It is shown that the greatest choppiness in motor energy increments with the recurrence or adequacy expanding.

Portrayals of the coordination number and agglomerate size dispersion for all cases are likewise done to examine the molecule agglomeration and breakage ways of behaving quantitatively. At the point when the ultrasonic recurrence is set at 20 kHz, the de-agglomeration impact of the ultrasonic field increments with the ultrasonic adequacy. At the point when the ultrasonic recurrence increments from 10 kHz to 20 kHz, the likelihood of the agglomerates framed by two essential particles increments quickly, while the agglomerates shaped by three to ten essential particles all decline. This shows that the ultrasonic vibration with a recurrence of 20 kHz can additionally break the little agglomerates into the littlest agglomerates or even individual particles.

To check the recreation results, near-covering tests have been performed with ultrasonic vibration-aided FB-ALD reactor on NCM811 particles, which can offer high energy thickness in car lithium-particle batteries (LIBs). The SEM images of the covered nanoparticles also show that the particles in the ultrasonic vibration-aided FB-ALD have been widely dispersed, resulting in more conformal layers and a higher covering proficiency.The trial information concurs well with the recreation results, which have checked the adequacy of the dynamic multiscale CFD-DEM model.

Teacher Chen Rong and different analysts in her gathering addressed inquiries regarding a few central issues while playing out the ultrasonic vibration-helped FB-ALD innovation:

Is the ongoing CFD-DEM model of FB with a size of a couple of millimeters sufficiently exact to foresee the molecule’s ways of behaving in a scale-up ultrasonic-vibration helped FB-ALD reactor?

Although the current multiscale CFD-DEM model covers scales just from the basic agglomerates to the FB with a size of a couple of millimeters, it has effectively uncovered the molecule agglomeration and breakage ways of behaving with ultrasonic help. With the improvement of the multiscale hypothesis and computational science, this model is accepted to be additionally created for a superior examination from lab-scale to assembling scale.

What effect does ultrasonic vibration have on agglomerate breakage?Is it always better to utilize higher ultrasonic frequencies?

“There is a fundamental worth to the ultrasonic recurrence.”At the point when the ultrasonic worth is lower than the basic worth, the typical molecule speed and the agglomerate size increment with the ultrasonic recurrence. In any case, when the ultrasonic recurrence surpasses this basic worth (for example 40 kHz) the particles start to agglomerate close to the vibrating wall.”

What angles would it be advisable for us to consider while upgrading the cycle boundaries or planning the ultrasonic-vibration FB-ALD reactor for the covering of huge amounts of nanoparticles?

“The selection of ultrasonic frequencies or amplitudes is influenced by a variety of factors, including reactor pressure, the identical between molecule firm powers, and the molecule size conveyance in the entire FB.” For the ideal plan reactor, information from nearby fields, for example, hydromechanics and mechanical design, is additionally required.

Scientists have proposed that different sorts of particulate materials will benefit a ton from the ultrasonic vibration-helped FB-ALD innovation. The help of ultrasonic vibration can really speed up the speed of liquid and particles close to the vibrating wall. The upgraded fluidization nature of nanoparticles likewise will undoubtedly work with the intensity of movement and forerunner dispersion in the entire FB-ALD reactor and the agglomerates, which can generally further develop the covering proficiency.

More information: Zoushuang Li et al, A combined multiscale modeling and experimental study on surface modification of high-volume micro-nanoparticles with atomic accuracy, International Journal of Extreme Manufacturing (2022). DOI: 10.1088/2631-7990/ac529c