An energy unit is an electric power generator that is suitable for creating power from hydrogen gas while releasing only water as a side effect. This profoundly productive clean energy framework is expected to play a critical role in the acceptance of the hydrogen economy, replacing ignition motors and batteries in vehicles and trucks, as well as power plants.

Nonetheless, the cost of platinum, which can eventually reach 30,000 USD per kg, has been a significant constraint, making energy component impetuses prohibitively expensive.The development techniques for profoundly performing impetuses have also been convoluted and generally limited.In like manner, the improvement of an effortless and versatile creation strategy for platinum-based energy unit impetuses is a critical test, along with upgrading reactant execution and solidity while utilizing a base measure of platinum.

To handle this issue, an examination group led by Prof. Sung Yung-Eun and Prof. Hyeon Taeghwan at the Center for Nanoparticle Exploration (CNR) inside the Establishment for Essential Science (IBS) in South Korea has found an original strategy for the creation of nanocatalysts.

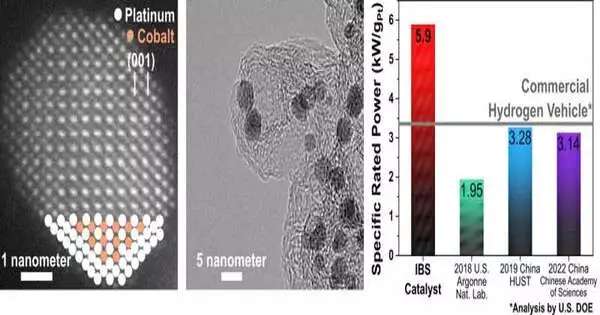

The scientists showed that these consistently estimated (3–4 nanometers) cobalt-platinum (Co-Pt) amalgam nanoparticles can be delivered by basic intensity therapy. This strategy combines the advantages of the impregnation technique’s simplicity with the colloidal technique’s precise control over the size and state of the nanocrystals.

The clever Co-Pt amalgam nanocatalysts created by the CNR-IBS group comprise two oppositely charged metal buildings, explicitly Co and Pt particles encompassed by bipyridine and chlorine ligands, individually.

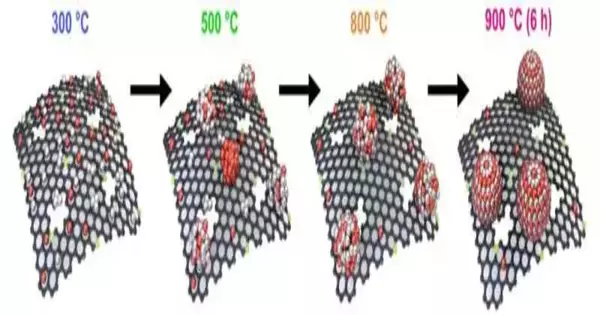

The examination group speculated that a basic intensity therapy would cause the bipyridine ligand to thermally disintegrate into a carbon shell that could safeguard the developing Co-Pt compound nanoparticles. They succeeded in obtaining a profoundly uniform nanocatalyst with nanoparticles of only 3-4 nanometer sizes after improving the intensity therapy condition.

Schematic outline of the development cycle of the Co-Pt amalgam nanocatalyst Straightforward intensity therapy at 900 °C could deliver molecularly requested Co-Pt nanoparticles on a carbon support. Credit: Foundation for Fundamental Science

In the nanocatalyst created by the gathering, Co and Pt particles were organized in a normal manner called the “intermetallic stage,” where the temperamental Co iotas are settled by the encompassing Pt molecules. Also, when nitrogen was really doped onto the carbon support, ionomers (proton guides) were homogeneously scattered over the whole impetus layer in the power module, which worked better with the stock of oxygen gas in the outer layer of the Co-Pt nanocatalyst.

These primary elements amounted to a much-upgraded power execution in the proton-trade film energy unit, showing a high, unambiguous evaluated force of 5.9 kW/gPt, which is about two times that of the ongoing exhibition in a business hydrogen vehicle. The group’s impetus has achieved the majority of the 2025 targets set by the US Department of Energy (DOE) with the goal of stable long-term activity of the power module.

The CNR-IBS group unequivocally accepts that this study would animate the improvement of cutting-edge energy unit impetuses. These discoveries would also contribute to improvements in the reactant execution and durability of combination nanocatalysts for various other electrocatalytic applications.

Prof. Hyeon expressed, “The plan for an original bimetallic compound as a forerunner material has been the basic beginning stage in this review.” “Through a basic and versatile strategy, we have fostered a stage of innovation to create a muddled type of composite nanocatalysts, and finally accomplished an improved energy unit power execution with less platinum utilized.”

Prof. Sung said, “An elite degree of power module execution has been accomplished in this examination, outperforming the greater part of the 2025 goals of the U.S. DOE by reducing how much platinum can contribute up to around 40% of the expense of energy units.” He added, “We expect that this review, along with some subsequent examinations, will extraordinarily affect the development of the hydrogen vehicle industry and the acknowledgment of the hydrogen economy soon.”

The review is distributed in the journal Energy and Ecological Science.

More information: Tae Yong Yoo et al, Scalable production of an intermetallic Pt–Co electrocatalyst for high-power proton-exchange-membrane fuel cells, Energy & Environmental Science (2023). DOI: 10.1039/D2EE04211H