Researchers created a single-material, single-stimulus microstructure that can outmaneuver even biological cilia. These programmable, micron-scale structures might be used for a variety of applications, including soft robotics, biocompatible medical devices, and even dynamic information encryption. For years, scientists have been striving to create small, artificial cilia for minuscule robotic systems capable of performing complex actions such as bending, twisting, and reversing. Building these smaller-than-a-human-hair microstructures often requires multi-step production techniques and varied stimuli to induce the intricate movements, limiting their wide-scale uses. Harvard John A. Paulson School of Engineering and Applied Sciences (SEAS) researchers have built a single-material, single-stimulus microstructure

Engineering

While developing new innovations, PC researchers and roboticists frequently draw motivation from creatures and other living life forms. This permits them to misleadingly recreate complex ways of behaving and motion examples to improve their frameworks' presentation, proficiency, and capacities. Specialists at Zhejiang Sci-Tech University and the University of Essex have as of late fostered a support learning method that can be utilized to control the development of a beaver-enlivened, single-legged robot. Their strategy, presented in a paper distributed in Robotics and Autonomous Systems, permits the robot to independently figure out how to perform swimming movements that look like those seen

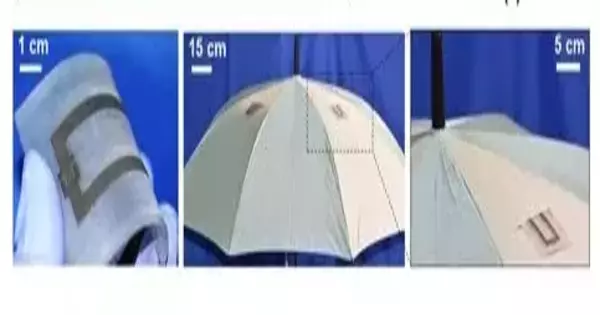

Have you, at any point, been caught in a startling heavy storm? Weather forecasting systems have generally attempted to forecast unfavorable weather events.These frameworks, in any case, are intensely reliant on massive, fixed, costly gear, for example, climate radar, obstructing timely updates on neighborhood atmospheric conditions for individual use.this hole in information and reasonableness, an exploration group from Osaka Metropolitan University and the University of Tokyo created an appendable and lightweight sensor sheet that includes an adaptable resistive sensor and a repository registering investigation. This single gadget permits synchronous constant estimation of raindrop volume and wind speed, detailing climate data

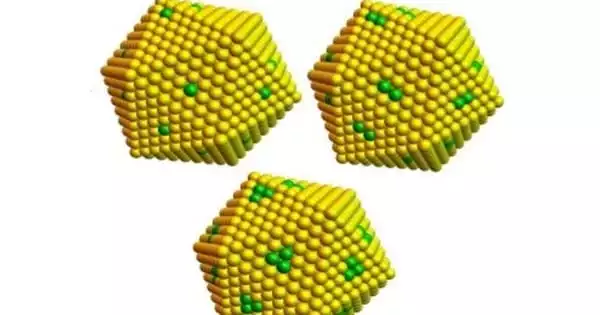

Researchers from Nanyang Technological University, Singapore (NTU Singapore) have figured out how to make biocement from squander, making the option, in contrast to ordinary concrete, considerably greener and more economical. Biocement is a sustainable type of concrete that commonly utilizes microorganisms to frame a solidifying response that ties soil into a strong square. The NTU researchers have now figured out how to utilize two normal waste materials, modern carbide ooze and urea—from the pee of warm-blooded animals—to make biocement. They facilitated a cycle in which the reaction of urea with calcium particles in modern carbide slime shapes a hard, strong,

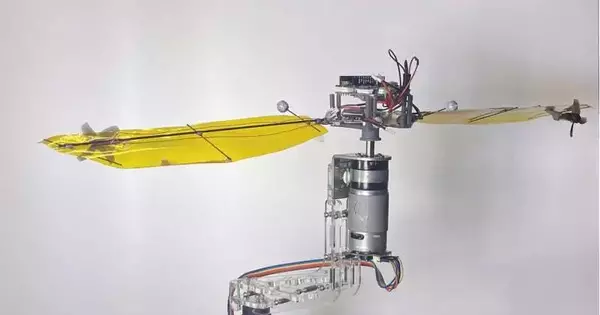

The avionics industry is under pressure from rising fuel costs and increased scrutiny of the natural and personal satisfaction influences of its aircraft.Scientists are searching for new techniques for minimizing costs while working on general productivity, and the moderately new market of automated ethereal vehicles (UAVs)—or drones—is no special case. "Our paper shows that a UAV using this kind of wing can support a good amount of load for small or medium-sized vehicles," Hoa, director of the Concordia Centre for Composites. UAVs are consuming a steadily developing space in flight circles. In another paper distributed in the journal Composite Structures, Suong Hoa

A group of engineers at the University of South Florida has developed a new technology that has the potential to change the way wearable electronic sensors are manufactured forever. They've found out a technique to speed up production without using polymer binders, which are the industry standard for printing flexible sensors, which are commonly used to monitor vital signs in medical settings. Their technology, which was featured on the cover of the journal ACS Applied Materials & Interfaces, uses corona discharge to create a strong electric field between binder-free functional powders like graphene and flexible, non-conductive surfaces like medical tape

Joel Berkson, a third-year doctoral understudy in the University of Arizona's James C. Wyant College of Optical Sciences and Steward Observatory, has fostered another way of unequivocally estimating the surfaces of radio-receiving wires, which are utilized to gather and concentrate radio waves for cosmology and satellite correspondence. These dish-formed receiving wires, similar to the ones portrayed in the 1997 film "Contact" featuring Jodie Foster, should be fabricated with an incredibly elevated degree of precision to function admirably. To guarantee their exactness, engineers measure the recieving wire surfaces utilizing metrology, a strategy that applies the study of estimation to assembling, instrumentation,